tHE iMPORTANCE OF dIRECT tIRE pRESSURE mONITORING sYSTEMS

Introduction

Driving with improperly inflated tires is a serious safety hazard that can lead to accidents, poor handling, and even tire blowouts. Direct Tire Pressure Monitoring Systems (TPMS) are an important safety feature in modern vehicles that help drivers maintain proper tire pressure and prevent potential issues. In this article, we’ll take a closer look at what direct TPMS systems are, how they work, their benefits and common issues, as well as helpful maintenance tips.

Definition of Direct Tire Pressure Monitoring Systems (TPMS)

Direct TPMS systems are designed to monitor the air pressure in each tire using sensors located on the valve stem. These sensors measure the actual air pressure inside each tire and wirelessly transmit that information to the vehicle’s computer system which then displays the readings on the dashboard.

Importance of TPMS in Vehicle Safety

Having properly inflated tires is essential for safe driving. Underinflated tires can cause increased fuel consumption, poor handling, uneven tread wear, overheating, blowouts and other serious problems that compromise driving safety.

In fact, according to the National Highway Traffic Safety Administration (NHTSA), underinflated tires are associated with more than 400 fatalities annually. Therefore, direct TPMS systems play a vital role in alerting drivers when tire pressure drops below recommended levels.

Overview of Different Types of TPMS

There are two types of TPMS systems: direct and indirect. Indirect TPMS relies on wheel speed to calculate tire pressure while direct TPMS uses sensors placed on each wheel to transmit real-time data about air pressure in the tires.

While indirect systems are still extremely useful (and making a comeback), direct TPMS is the more reliable and a highly recommended type of system for monitoring tire pressure in modern vehicles.

Benefits of Direct TPMS

In addition to helping drivers maintain proper tire pressure levels, direct TPMS offers several benefits that can enhance vehicle safety. For instance, maintaining proper tire pressure can improve fuel efficiency by reducing rolling resistance and minimizing tread wear.

Properly inflated tires also reduce stopping distance and improve handling which are critical factors in avoiding accidents. Direct TPMS provides real-time diagnostic information that allows drivers to make timely decisions on what actions to take to keep their vehicle in good condition.

Direct TPMS systems are a crucial safety feature that help drivers monitor their vehicle’s tire pressure levels accurately and maintain safe driving conditions on the road. In the next section, we’ll look at how direct TPMS works and its components.

How Direct TPMS Works

Components of a Direct TPMS System

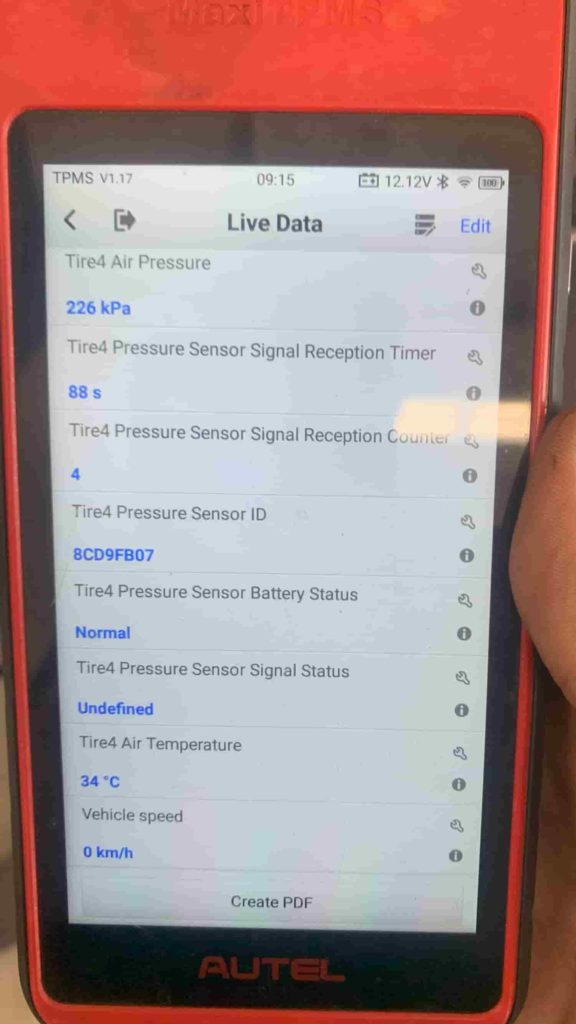

Direct Tire Pressure Monitoring Systems (TPMS) work by using sensors that are located inside the tire to measure the pressure of the air. These sensors are connected to the vehicle’s onboard computer system, which then displays the readings on the dashboard. The sensors used in direct TPMS can be either internal or external.

The internal sensor is mounted inside the tire on the valve stem and requires a special valve stem replacement during installation. On the other hand, external sensors are mounted outside of tires and do not require any special modifications to be made. (External sensors are aftermarket)

Direct TPMS systems also have a central receiver that is responsible for collecting data from all four sensors and transmitting it to the vehicle’s computer system. This communication network is usually established through radio frequency signals.

How Each TPMS Component Works:

Tire Pressure Sensors

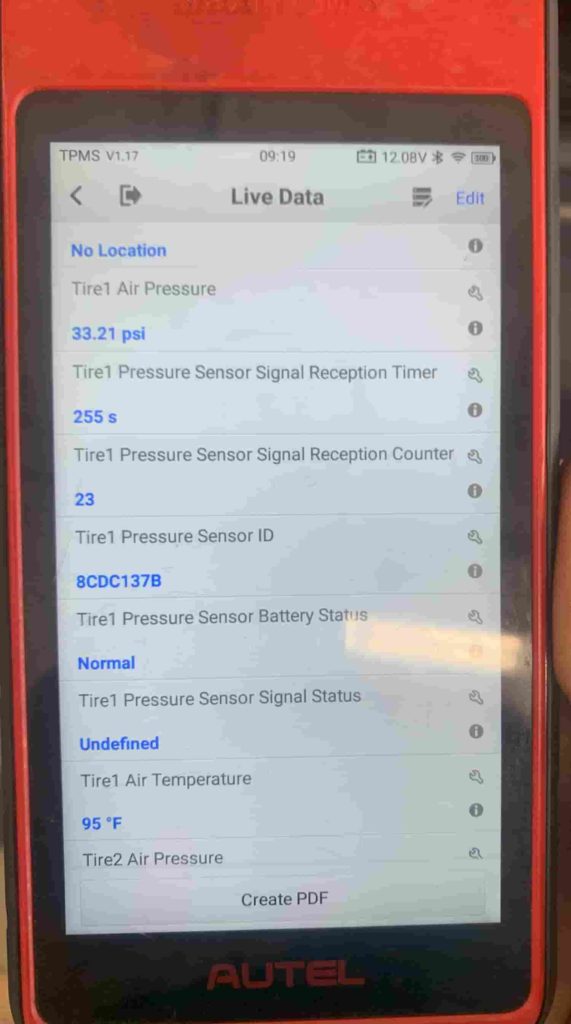

Tire pressure sensors are the heart of a direct TPMS. These devices are built into the tire and measure the pressure directly. Most of these sensors are piezoresistive sensors, meaning they measure pressure changes via resistance. The sensor has a diaphragm that flexes with the change in pressure. This flex alters the resistance in the electronic circuit, which is then interpreted as a change in pressure. Each sensor also has its own unique ID and this ID is transmitted along with the pressure information. This allows the TPMS control module to know which sensor (and therefore which tire) each signal is coming from. The sensors are usually located as part of the tire valve or are strapped to the inside of the wheel. As the wheel turns, the sensor measures the pressure and transmits this information to the TPMS control module. Each sensor is powered by a small lithium battery that can last for several years but is not typically user-serviceable. Once the battery in a sensor dies, the entire sensor unit needs to be replaced.

Radio Frequency (RF) Transmission

The data from the tire pressure sensors is transmitted wirelessly to the TPMS control module via Radio Frequency (RF) signals. This is essentially the same technology used in remote controls, wireless doorbells, and many other types of wireless devices. The RF transmission happens on a specific frequency, usually in the 315 MHz or 433 MHz range, depending on the region and the specific system. The data transmitted includes both the pressure reading and the sensor’s unique ID. This transmission can occur every few seconds, or it may be triggered only when there’s a significant change in pressure to conserve battery power. The RF signals are broadcasted to a receiver in the TPMS control module. The receiver decodes the signals, translating them into data that the control module can understand and act upon.

TPMS Control Module

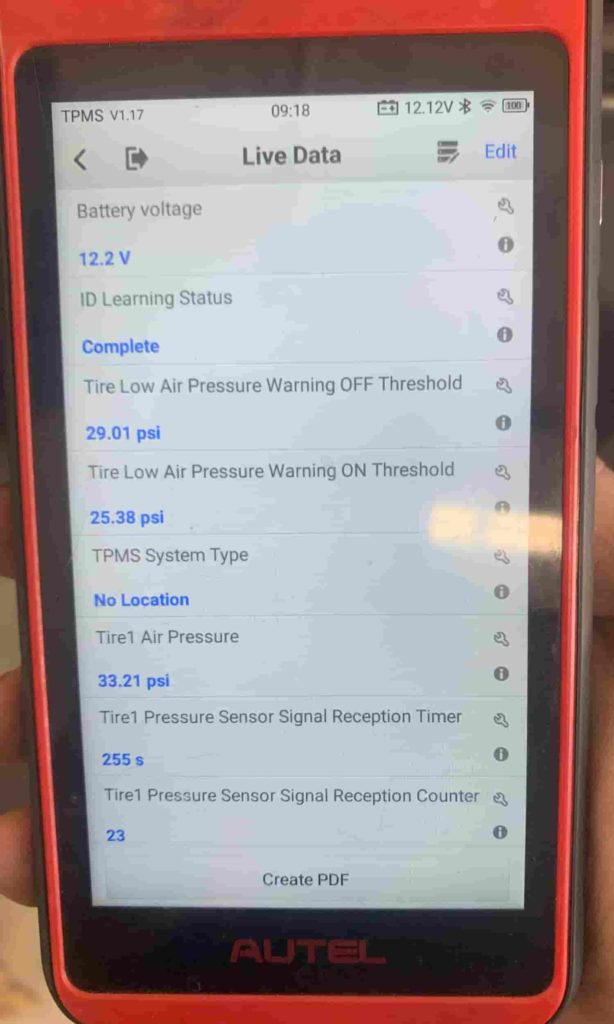

The TPMS control module, sometimes referred to as the receiver or Electronic Control Unit (ECU), is the central hub of the TPMS. It receives the RF signals from each tire pressure sensor, decodes the signals, and then processes the information. The control module matches the unique ID of each sensor to the corresponding tire, so it knows which tire each pressure reading is coming from. (this is why when you rotate your tires it’s essential to reset your TPMS. If you don’t, it might think the front tires are in the rear and rear tires in the front) It compares the pressure readings to a pre-set range (the recommended tire pressure levels specified by the vehicle’s manufacturer). If any tire’s pressure is outside the recommended range, the control module will trigger a warning. This warning typically takes the form of a light on the vehicle’s dashboard, often shaped like a tire with an exclamation mark inside it.

In newer systems, the TPMS control module will also send detailed information to the vehicle’s infotainment display, such as the specific pressure readings for each tire or the temperature inside the tire. Sometimes the TPMS control modules are integrated with other vehicle systems. For example, they might adjust the vehicle’s Electronic Stability Control (ESC) system based on tire pressure information, as changes in tire pressure can affect vehicle handling.

Sensors and Their Placement in the Tires

The placement of these sensors on each tire valve stem would vary depending on your vehicle’s manufacturer specifications. Sensors that are either part of the valve stem as one unit or are attached directly to the rim using a metal band.

Benefits of Direct TPMS

Improved Fuel Efficiency & EV Range

One of the primary benefits of direct TPMS is improved fuel efficiency. When tires are underinflated, it creates more resistance between the road and the tire, which requires more effort from the engine to move the car. This increases fuel consumption, reduces gas mileage, and leads to frequent trips to the gas station. It has the same effect on electric vehicles. When tires are properly inflated your EV uses less energy resulting in extended battery life and enhanced EV range!

Direct TPMS sensors allow drivers to monitor tire pressure in real-time, ensuring that tires are always inflated to their optimal pressure levels. According to a study by the National Highway Traffic Safety Administration (NHTSA), properly inflated tires can improve gas mileage by up to 3%. That may not seem like much but if you drive 50,000 miles a year that’s an extra 1500 miles!

Increased Tire Life

Direct TPMS systems also help prolong the life of your tires. When tires are underinflated or overinflated, they wear out faster and unevenly.

This can lead to bald spots and reduce traction on wet or slippery roads. By maintaining proper tire pressure through direct TPMS, you can prevent premature wear and tear on your tires and make them last longer.

Enhanced Safety Features

Another major benefit of direct TPMS is enhanced safety features for drivers and passengers in a vehicle. Underinflated or overinflated tires are more prone to blowouts or punctures, which can cause serious accidents on highways or busy roads. By regularly monitoring tire pressure with direct TPMS sensors, you can identify potential problems before they become dangerous situations on the road.

In addition, direct TPMS systems also improve overall vehicle handling and stability by ensuring that all four tires have equal air pressure levels. This reduces swaying or bouncing while driving at high speeds or making sharp turns.

Better Handling & Stability

Properly inflated tires offer better handling performance than improperly inflated ones. With a direct TPMS alerting you for low tire pressure, you get a warning before things get dangerous.

This way, tire pressure is never forgotten and left unchecked for long periods of time. Better handling and stability on the road means better control over your vehicle with less likelihood of losing control.

Cost Savings

Direct TPMS also leads to cost savings. By maintaining proper tire pressure, you can extend the life of your tires and reduce your fuel consumption, which translates into fewer trips to the gas station. In addition, by identifying potential problems early on with direct TPMS sensors, you can avoid costly repairs or replacements down the road.

Overall, direct TPMS is an essential component of modern vehicles that offers numerous benefits for drivers in terms of safety, efficiency, and cost savings. By investing in a reliable direct TPMS system and regularly checking tire pressure levels using this technology, drivers can enjoy better fuel efficiency, increased tire life span, enhanced safety features on the road while saving money at the same time.

Common Issues With Direct TPMS

Direct Tire Pressure Monitoring Systems (TPMS) are known for their accuracy and reliability, but like any technology, issues can arise that may affect their performance. In this section, we will discuss some of the most common problems that drivers encounter with Direct TPMS systems.

Sensor Failure

One of the most common issues with Direct TPMS is sensor failure. The sensors are responsible for measuring tire pressure and transmitting that information to the vehicle’s computer system.

Over time, these sensors can become damaged or fail due to wear and tear. When a sensor fails, it can cause inaccurate readings or even prevent the system from working altogether. Another common issue is that the sensor valve can crack and break completely. This usually happens to metal valves that are exposed to the elements for years on end.

To prevent sensor failure, it is essential to make sure they are installed correctly during routine maintenance checks and replacements when required. Drivers should also avoid damaging or over-tightening the sensors during tire changes or replacements.

Incorrect Readings Due to Environmental Factors

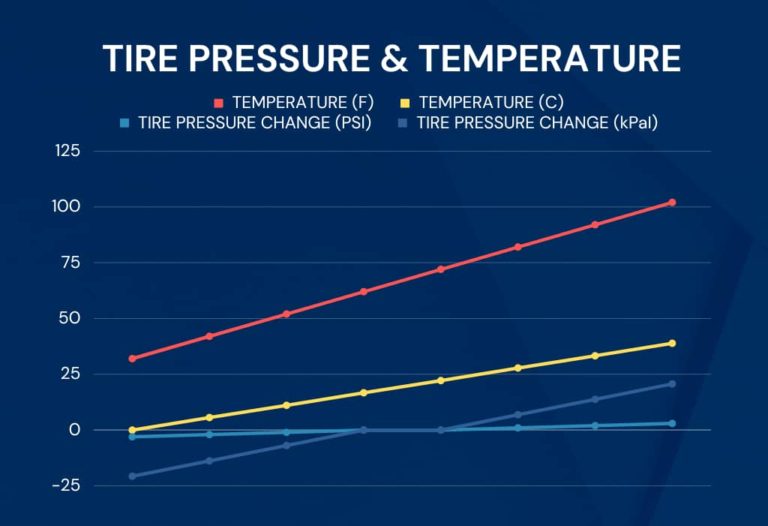

Another issue with Direct TPMS is incorrect readings due to environmental factors such as temperature changes or altitude differences. Tire pressure changes based on these variables, which can cause inaccurate readings from the sensors.

To avoid incorrect readings due to environmental factors, drivers should check the tire pressure manually at least once a month and adjust it if necessary according to manufacturer recommendations. Additionally, they should be aware of how environmental conditions can affect tire pressure and driving safety Two general rules to keep in mind: For every 10 degree change in temperature, your tire pressure will change in the same direction by about 1 Psi. And for every 1.5 Km change in altitude, your tire pressure will also change by about 1 Psi.

Battery Life And Replacement

Direct TPMS systems use batteries in their sensors for power. They are very similar to wrist watch batteries. Over time these batteries will eventually lose their charge resulting in malfunctioning sensors or no signal being transmitted at all leading to warning lights appearing within your vehicle display systems – alerting you of an issue.

It is crucial for drivers to regularly check battery life during annual maintenance visits with a professional mechanic who has experience working on your particular make and model of car/truck/vehicle being used so they can prevent any issues before they occur. When batteries are dead or dying in the sensors, the entire sensor must be replaced. This is because to access the battery you have to break open the sensor and then, well, you have a broken sensor.

While they are generally reliable and accurate, it is still important to be aware of common issues such as sensor failure, incorrect readings due to environmental factors, and battery life. By performing regular maintenance checks and staying knowledgeable about how these systems work, drivers can help ensure their safety on the road.

Common Myths About TPMS: Misconceptions

Myth 1: If the TPMS light isn’t on, my tire pressure is fine.

Fact: The TPMS light usually comes on only when the tire pressure is significantly outside the recommended range, typically by 25% or more. Even if the light isn’t on, your tires could still be underinflated or overinflated by a small amount that could affect your vehicle’s fuel efficiency and handling. Regular manual checks with a tire pressure gauge are still recommended.

Myth 2: TPMS isn’t necessary; I can tell by looking if a tire is low.

Fact: While it’s true that a severely underinflated tire might look visibly low, many tires can lose a significant amount of air pressure without any visible signs. TPMS provides an important safety net by alerting you to pressure issues that you might not notice otherwise.

Myth 3: TPMS eliminates the need to manually check tire pressure.

Fact: While TPMS is a great tool for monitoring tire pressure, it doesn’t entirely replace manual checks. As mentioned earlier, TPMS warning lights usually only trigger when tire pressure is significantly outside the recommended range. Regular checks with a tire pressure gauge can help ensure that your tires are optimally inflated.

Myth 4: If I replace my tires, I need to replace my TPMS sensors as well.

Fact: TPMS sensors typically have a lifespan of about 5-10 years, which is often longer than the lifespan of the tires. When you replace your tires, you don’t necessarily need to replace the sensors unless they’re not working properly or the batteries are nearing the end of their lifespan. If you are replacing wheels, you either need to swap over the sensors from old wheels or new wheels or get a second set of sensors for the new wheels.

Myth 5: All cars have TPMS.

Fact: While it’s true that most new vehicles come with TPMS as a standard feature, it’s not universal. In the United States, for example, TPMS has only been mandatory on new passenger vehicles since the 2008 model year. Older vehicles might not have TPMS, and it’s not required on all types of vehicles in all regions.

Maintenance & Troubleshooting Tips for Direct TPMS

Regularly Checking Tire Pressure Manually

One of the most crucial aspects of maintaining a direct TPMS system is regularly checking tire pressure manually. Despite the advanced technology in direct TPMS systems, they are still subject to inaccuracies caused by environmental factors or technical malfunctions.

This is why it is important to manually check your tire pressure at least once a month and before any long trips. To manually check your tire pressure, you will need a tire gauge.

How to Adjust Tire Pressure Manually

Make sure the tires are cold.

Remove the valve cap from the tire.

Press the tip of the tire pressure gauge onto the valve and read the pressure.

If the tire pressure is below the recommended level , fill the tire with air until the correct pressure is reached. If the tire pressure is above, release air until it’s at exactly. (Press the metal stem in the center of the tire valve. You can use any object like a screwdriver to do this. Be gentle.)

After adjusting the tire pressure, don’t forget to put the valve caps back on to prevent leaks and keep dirt and moisture out.

Repeat this process for each tire, including the spare if applicable.

What is "Cold Pressure"?

To get a correct and accurate tire pressure reading, check the air pressure when the car has been sitting for a while. This is known as checking the “cold pressure” after the car hasn’t moved for about three hours or more. Driving heats up your tires, causing the air inside to expand and show a falsely high pressure reading. So, don’t adjust your tire pressure right after driving or your tires will end up overinflated!

Resetting the System After Tire Rotation or Replacement

When you rotate or replace tires, it changes the position of the sensors relative to their previously registered location. This can cause incorrect readings or trigger a warning light on your dashboard. To avoid this issue, you will need to reset your direct TPMS system after rotating or replacing tires.

The process for resetting varies based on make and model but typically involves pressing a button inside the vehicle while in “learn” mode and following specific instructions outlined in your owner’s manual. It is important to follow these instructions carefully as improperly resetting could lead to inaccurate readings. In the absence of a tire pressure reset button in your vehicle, the resetting process involves inflating your tires to their proper pressure levels, followed by driving the vehicle for a few miles at a specific speed.

Troubleshooting Common Issues

Despite regular maintenance efforts, issues may still arise with direct TPMS systems which require troubleshooting techniques to identify and resolve them. One common issue with direct TPMS systems is sensor failure due to battery depletion or damage from road debris.

If you notice that one of your tires consistently displays an incorrect pressure reading on your dashboard while all other tires appear fine when manually checked, it is likely that the sensor has failed. Another symptom of battery failure is for the tire pressure light to flash or blink. This indicates a TPMS malfunction within the system either due to a dying sensor or for driving the vehicle with a wheel missing a sensor. In this case, you will need to replace the sensor to restore proper functionality.

Another issue that can arise is incorrect readings due to environmental factors such as temperature changes or altitude variations. To avoid this issue, it is recommended to check tire pressure when your tires are cold and at the same location each time.

Regular maintenance and troubleshooting efforts are crucial for ensuring the proper functioning of a direct TPMS system. By manually checking tire pressure regularly, resetting the system after tire rotation or replacement, and troubleshooting common issues such as sensor failure or environmental inaccuracies, drivers can ensure their direct TPMS system contributes to enhanced safety features while improving fuel efficiency and increasing tire life.

How to Install and Calibrate New Sensors

Installing new TPMS sensors into a wheel is a straightforward process, generally done during tire changes. After removing the tire from the wheel, the old sensor is carefully removed, usually from the valve stem position, and the new one is then fitted into place. It’s crucial to ensure that the new sensor is compatible with your vehicle’s TPMS system. Once the new sensor is installed and the tire is refitted, the sensor needs to be registered to the vehicle’s Electronic Control Unit (ECU). This process, often referred to as “relearning,” involves programming the new sensor’s unique ID code into the ECU so that it recognizes signals from the new sensor. (we recommend taking a picture of each new sensor before installing them so that you have the ID code accessible) This process varies by vehicle, with some vehicles capable of doing this automatically while others may require specific steps, tools, or even a visit to a professional mechanic or dealership. Always refer to the vehicle’s manual or manufacturer’s guidelines for precise instructions.

Conclusion

The Future of TPMS

As we look towards the horizon, we envision a bright future for TPMS with potential developments promising improved safety and efficiency. Emerging advancements point towards TPMS systems gaining greater precision, with future sensors capable of providing real-time data on tire tread depth, temperature, and possible damage detection. In tandem with the rise of integrated vehicular systems, we anticipate the interconnection of TPMS with braking and stability control systems to offer seamless real-time vehicle monitoring and enhanced safety.

Final Thoughts

In wrapping up our deep dive into Direct Tire Pressure Monitoring Systems (TPMS), it’s clear that this technology stands as a pivotal asset for modern-day driving. It’s more than just a tool—it’s an essential safety and efficiency facilitator that has transformed our driving experiences. From alerting us to pressure irregularities, enhancing fuel economy, and increasing tire longevity, TPMS serves as an unsung hero in our vehicles. Despite potential issues, understanding its functioning, benefits, maintenance, and troubleshooting ensures we can reap the rewards this system offers.

The world of TPMS is ever-evolving, and as we head into the future, we can anticipate this technology becoming an even more integral part of our driving lives. Remember, being informed and proactive is the key. So, buckle up, keep your tires checked, and enjoy the journey—TPMS has your back!

faq

Q: What does it mean when your TPMS light comes on?

A: When your TPMS light comes on, it means the system has detected a tire with pressure that is outside the manufacturer’s recommended range. This could be due to underinflation or overinflation. Some vehicles have an advanced TPMS that can indicate which tire is causing the issue and provide its pressure reading.

Q: Is it OK to drive with the TPMS light on?

A: It’s generally safe to drive short distances with the TPMS light on, but you should address the issue as soon as possible. Driving for a prolonged period with incorrect tire pressure can lead to reduced fuel efficiency, poor handling, increased tire wear, and in severe cases, a tire blowout. It’s best to determine what the problem is, is there a slow leak? Is it a nail or screw? Is the bead seal leaking? Determine how serious of an issue you have and then determine how dangerous the situation is.

Q: How do you solve TPMS?

A: If your TPMS light comes on, first check the pressure in all of your tires using a reliable tire pressure gauge. If a tire is underinflated or overinflated, adjust the pressure to match the manufacturer’s recommended level (often listed on a sticker inside the driver’s door or in the vehicle’s manual). If the light remains on after adjusting the tire pressures and driving for a short distance, there may be an issue with one of the TPMS sensors or with the system itself. In this case, you may need to take your vehicle to a professional for service. Ourwebsite TPMSRESET.COM has a substantial database of how to reset many vehicle tire pressure lights. Just use the search bar in the top right corner and search for your made and model car!

Q: How do I check my TPMS?

A: TPMS self-checks every time you start your vehicle. The TPMS light on your dashboard should illuminate briefly when you start the engine – this is a bulb check to ensure the system is operational. If the system detects an issue with tire pressure during driving, the TPMS light will flash and then stay on. Some advanced systems may also provide a warning message or a display of each tire’s pressure. For a more comprehensive check of your TPMS, you may need to visit a professional mechanic or use a TPMS diagnostic tool.

Please note that this blog post contains Amazon affiliate links. This means that if you make a purchase through one of these links, we at TPMSRESET.com may earn a small commission at no extra cost to you. We only recommend products that we personally use and believe in. Thank you for supporting us.