Introduction

When it comes to working on your vehicle, safety should always be your utmost priority. One of the essential tools for ensuring a safe and secure working environment is the automotive jack stand.

Jack stands play a crucial role in providing stability and support while you perform maintenance tasks or repairs underneath or with your vehicle off the ground. In this comprehensive guide, we will delve into the importance of using automotive jack stands and provide you with an overview of the topic, equipping you with the knowledge necessary to work confidently and without compromise.

The Importance of Using Automotive Jack Stands

Using automotive jack stands is not merely a recommendation; it is an absolute necessity for anyone attempting to work beneath their vehicle. The primary purpose of these devices is to provide a stable foundation that prevents any accidental movement or collapse, ensuring your safety while manipulating components or performing repairs.

Relying solely on a hydraulic floor jack can be extremely risky, as hydraulic systems can fail or experience leaks, leading to sudden drops and potential catastrophes. Moreover, even if the hydraulic floor jack seems sturdy enough initially, it is not designed for prolonged weight-bearing purposes.

Continuous stress on its parts and mechanism can ultimately result in failure. By employing appropriately rated jack stands alongside your floor jack, you create redundancy in safety measures that significantly minimize the risk of accidents or injuries.

Understanding Automotive Jack Stands

Definition and Purpose of Jack Stands

Automotive jack stands are indispensable tools used to provide support and stability when working beneath a raised vehicle. Their primary purpose is to prevent the vehicle from falling, ensuring the safety of both the technician and the vehicle. Unlike hydraulic jacks or scissor jacks, which are primarily used for lifting vehicles, jack stands are designed specifically for load-bearing support.

A jack stand typically consists of a strong metal frame with adjustable height settings and a base that provides excellent stability. The top part of the stand features a cradle or saddle-like structure that supports the vehicle’s weight.

It is crucial to choose jack stands with adequate weight capacity to handle the specific load requirements of your vehicle. Relying solely on hydraulic jacks or other lifting devices without utilizing jack stands can be extremely dangerous, as they lack the necessary stability to hold up a heavy vehicle for an extended period.

Different Types and Designs Available in the Market

There are several types and designs of jack stands available in today’s market, each offering various features tailored to specific needs and preferences. The most commonly used types include tripod-style stands, ratchet-style stands, pin-style stands, and axle stands.

Tripod-style jack stands offer excellent stability due to their three-legged design, providing enhanced balance when supporting heavy loads. They often have wide bases that distribute weight evenly across multiple points.

Ratchet-style jack stands feature adjustable height settings using a ratcheting mechanism. This design allows for easier adjustment when positioning under different lift points on a vehicle’s frame.

Pin-style jack stands provide simplicity in their design by utilizing pins inserted into holes at different height intervals along their vertical columns. These can be easily adjusted by removing and reinserting pins into different holes until reaching the desired height.

Axle stands operate differently from other types by supporting the vehicle using stands placed beneath the axle instead of on the frame. These stands are particularly useful when working on vehicles without a frame or when additional clearance is required.

When selecting jack stands, always consider factors such as weight capacity, height range, stability features, and overall build quality to ensure they are appropriate for your specific vehicle and tasks at hand. Cheapest is definitely not always best in this case!

Selecting the Right Jack Stands

Weight Capacity Considerations

When it comes to selecting jack stands one of the most crucial factors to consider is their weight capacity. Each vehicle has its own weight specifications, and it is essential to choose jack stands that can support the weight of your vehicle.

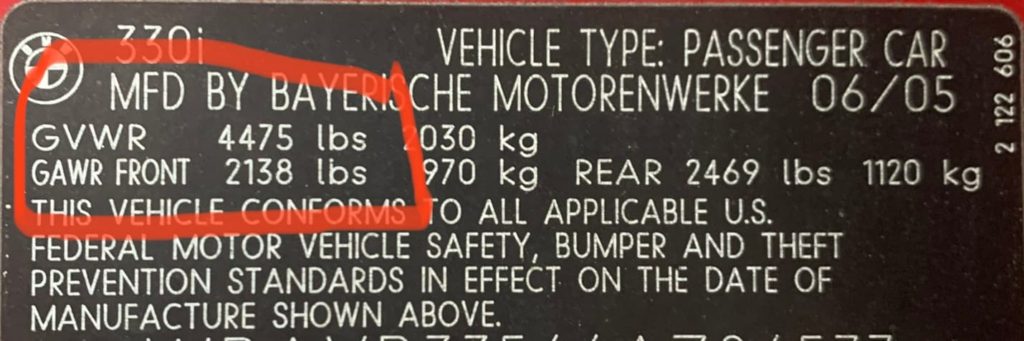

You can find this information in your vehicle’s owner’s manual, by researching online sources or by checking the GVWR (gross vehicle weight) on the white sticker on the inside of the driver side door panel. Remember that using jack stands with inadequate weight capacity can lead to catastrophic accidents and serious injuries.

To determine the appropriate weight capacity for your jack stands, you need to consider not only the overall weight of your vehicle but also any additional load it may carry. This includes passengers, cargo, and aftermarket modifications like roof racks or towing equipment.

It’s advisable to choose jack stands with a slightly higher weight capacity than what is actually required for your vehicle’s specifications. If your vehicle weighs 4300 pounds, use a jack stand that can handle at least 5000 pounds. This provides an extra margin of safety and ensures that the jack stands will be able to handle unexpected shifts in weight distribution.

Quality and Durability Factors

When selecting jack stands it’s imperative to prioritize quality and durability over price alone. Investing in high-quality jack stands increases both their reliability and longevity while reducing the risk of accidents caused by faulty equipment.

Look for jack stands constructed with robust materials such as steel or aluminum, which offer excellent strength and stability. Pay attention to features like weld quality; ensure that all welds are smooth and free from cracks or other defects that could compromise structural integrity.

Inspect critical components such as locking mechanisms or adjustable height mechanisms to ensure they are well-built and function smoothly. Certifications from reputable organizations such as ANSI (American National Standards Institute) or ASME (American Society of Mechanical Engineers) are also indicators of quality assurance. These certifications ensure that the manufacturer has adhered to stringent safety standards during the design and production processes. By choosing jack stands with proper certifications you can mitigate potential risks.

Choosing the Appropriate Height Range

Another essential aspect to consider when selecting jack stands is their height range. The height range determines how low or high you can position your vehicle for various maintenance tasks. Different vehicles have different ground clearances, so it’s crucial to choose jack stands that can accommodate the lowest point of your vehicle while providing ample working space.

When determining the appropriate height range consider both your current needs and any potential future requirements. For example, if you plan on performing tasks like changing tires or inspecting brakes, a moderate height range might suffice.

If you anticipate more extensive repairs or modifications in the future that require accessing undercarriage components, opting for jack stands with a higher maximum height becomes essential. Remember that using jack stands outside their recommended height range poses significant safety risks.

Jack stands that are too short may not provide adequate clearance or stability, while those that are too tall may compromise stability and increase the risk of tipping over your vehicle. Carefully assess your specific needs and select jack stands with an appropriate height range to ensure safe and efficient maintenance experiences.

Gathering Necessary Tools and Equipment

It’s imperative to gather all the necessary tools and equipment to ensure a smooth and efficient process but also enhances safety. Firstly, you’ll need a reliable jack to lift your vehicle off the ground securely. It is recommended to use either a hydraulic floor jack or a scissor jack that is suitable for your vehicle’s weight capacity.

In addition to the jack a lug wrench is essential for loosening and tightening lug nuts on your vehicle’s wheels. We suggest buying the correct socket size (17mm, 19mm, or 21mm) and either an impact ratchet or an extended handle 1/2 in ratchet. This will make your life much easier.

Wheel chocks are another indispensable tool that helps prevent unintended movement of the vehicle while it’s raised on jack stands. Placing wheel chocks in front of and behind the wheels opposite to those being lifted will act as an extra layer of security against any potential rolling mishaps during the process. The less movement, the better!

Identifying a Safe Working Area

Finding an appropriate working area is paramount when using automotive jack stands safely. Start by selecting level ground that provides stability throughout the operation; uneven surfaces or slopes can compromise safety and stability while working under a lifted vehicle. If your driveway is sloped, use the street. If the street is sloped, use a parking lot. Don’t take any unnecessary risks! Clear any debris or obstacles from around the designated work area to avoid tripping hazards or damage to equipment.

Ensure adequate space around your vehicle that allows you easy access without feeling cramped or restricted during each step of using jack stands. Ample room will enable you to maneuver tools efficiently and give you peace of mind as you work under your automobile.

Ensuring Proper Tire Inflation and Parking Brake Engagement

Prioritize tire inflation before lifting your vehicle with jack stands. Properly inflated tires provide stability and a solid foundation for the entire process. Check the manufacturer’s recommended tire pressure for your specific vehicle and use a reliable tire pressure gauge to ensure accurate readings. Inflate or deflate the tires as needed to adhere to the recommended pressure range.

Engaging the parking brake is equally crucial when preparing to lift your vehicle with jack stands. The parking brake acts as an additional safety measure by preventing any inadvertent movement while you are working underneath it.

This small but significant step ensures that your vehicle remains stationary, reducing potential hazards and allowing you to focus on safely completing each task. When all these preparatory steps are carefully executed, you are well on your way to using automotive jack stands safely and confidently.

Step-By-Step Guided to Using Jack Stands Safely

Step 1: Lifting the Vehicle with a Hydraulic Floor Jack or Scissor Jack

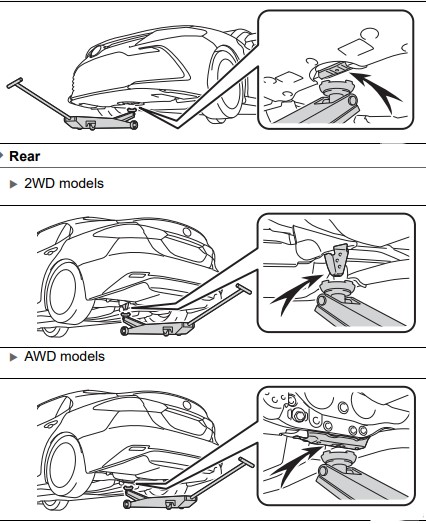

Positioning the jack correctly is paramount to ensuring a safe lifting process. Before you start jacking up your car,, refer to your vehicle’s owner’s manual for the recommended jacking points. These designated lift points are typically marked on the frame or indicated in the manual. (There will be pictures of exact locations to put the jack!) It is crucial not to deviate from these specified areas as using other points can damage the vehicle or compromise safety.

Once you have identified the proper jacking points, position your hydraulic floor jack or scissor jack underneath them. Begin slowly pumping the jack handle using measured and controlled motions. As you do so, keep a close eye on how your vehicle responds to ensure stability. Before proceeding further, it is essential to double-check that your vehicle is securely lifted and balanced on the jack.

Gently give your car a slight shake to confirm stability. If any wobbling occurs, lower it immediately and repeat the process of positioning and lifting until you achieve a secure and stable elevation.

Step 2: Placing Jack Stands Correctly

Identifying a secure location on your vehicle’s frame or designated lift points is crucial for placing jack stands correctly. The ideal areas for supporting your vehicle with jack stands are often marked by notches or reinforced sections on the frame itself. When you look under your car with a flashlight you will usually see round or square rubber blocks to indicate a lifting point. If your vehicle does not have these blocks your vehicle’s frame is usually the place to use. These spots offer excellent structural integrity and minimize any risk of damaging fragile components or compromising stability.

Once you have identified these secure locations, position each stand beneath them systematically. It is vital to ensure that each stand is evenly spaced apart from one another for balanced weight distribution.

After placing the stands in their correct positions, adjust their height accordingly so that they match that of your hydraulic floor jack. This step helps maintain an even elevation across all support points while also providing additional safety measures to prevent any potential instability or unexpected shifts in your vehicle’s position. All jack stands should be at the same height!

Step 3: Lowering the Vehicle Onto Jack Stands

Now that the jack stands are appropriately positioned it’s time to lower your vehicle onto them safely. Start by carefully releasing the pressure from your hydraulic floor jack allowing the weight of the car to transfer onto the jack stands. To do this, slowly turn the release valve or lever on your jack to ensure a controlled descent.

Keep a close eye on each jack stand as you lower your vehicle. Verify that they are firmly accepting the weight and evenly supporting it without any signs of strain or instability.

Take your time during this process to ensure a smooth transition because rushing can lead to accidents or damage. Once your vehicle is resting securely on all of the jack stands with no sign of movement or wobbling, you can consider it successfully lowered and ready for any maintenance or repair work.

Conclusion

Using automotive jack stands safely is essential for both personal safety and protecting your vehicle from potential damage. By following this step-by-step guide you can confidently put your car up in the air! Investing time in identifying the correct lift points, double-checking stability throughout each step, and ensuring proper height adjustment for both jacks and stands forms a solid foundation for safe practices. By adhering to these guidelines you demonstrate responsibility towards maintaining a secure working environment when undertaking any automotive maintenance.

Remember, safety should always be prioritized when working under a raised vehicle! Don’t rush and do it right!