Introduction

From the initial invention of solid rubber tires in the late 19th century to the advancements in modern-day pneumatic tires, the technology has continuously evolved to meet the ever-growing demands of vehicles and drivers. However, as we look towards the future there is a pressing need for further innovation in tire technology.

The challenges we face today, such as environmental sustainability, road safety, and energy efficiency, call for a paradigm shift in how we approach tire design and manufacturing. One of the key areas where we anticipate significant progress is in tire materials.

Traditionally, tires have been predominantly made from petroleum-based synthetic rubber compounds. However with an increasing focus on sustainability and reducing our carbon footprint, researchers are exploring alternative materials that can offer comparable or even superior performance while being more environmentally friendly.

Sustainable materials such as natural rubber derived from renewable sources like guayule or dandelion latex show promise as they reduce dependence on fossil fuels while maintaining essential tire properties like grip and durability. The impact of these new materials on tire performance cannot be understated.

Manufacturers are keenly aware that consumers demand tires that deliver excellent traction on various road surfaces without compromising fuel efficiency or safety. By incorporating sustainable materials into the tire production processes, it’s possible to develop innovative solutions that address these concerns without sacrificing performance.

Furthermore, intelligent tires represent another exciting aspect of future upgrades in this domain. Smart or intelligent tires are equipped with advanced sensor technology that allows them to monitor crucial parameters such as pressure, temperature, tread wear patterns, and even road conditions in real-time.

These sensors provide valuable data that can be used to enhance overall vehicle performance and safety by alerting drivers about potential issues before they escalate into major problems. The integration of sensors within intelligent tires holds great potential for revolutionizing road safety by providing early warning systems for dangerous driving conditions caused by factors such as rain-slicked surfaces or icy roads.

Additionally these sensors enable optimized tire maintenance by providing accurate information about tire wear patterns and pressure levels, resulting in longer-lasting tires and improved fuel efficiency. The future of tires is poised to bring about a transformational shift in the automotive industry.

Through advancements in tire materials, the integration of intelligent technologies, and a commitment to sustainability, we can expect tires that not only perform better than their predecessors but also contribute positively towards environmental conservation. The journey towards this future is an exciting one filled with groundbreaking innovations that will shape the driving experience for generations to come.

The Evolution of Tires

The evolution of tires has been a fascinating journey marked by significant advancements in technology and materials. Initially, tires were simple bands of rubber wrapped around wooden wheels, serving the purpose of reducing friction and providing a smoother ride.

With the advent of the industrial revolution and the rise of automobiles, tire design underwent a substantial transformation. The introduction of pneumatic tires in the late 19th century revolutionized the industry as it offered enhanced comfort and improved road grip.

These early air-filled tires consisted of inner tubes made from rubber that held compressed air to provide cushioning effect. Over time tire manufacturers experimented with various materials to improve durability and performance.

The development of synthetic rubber during World War II paved the way for more resilient and long-lasting tires. In subsequent years advancements such as steel-belted radials brought about a paradigm shift in tire construction by reinforcing them with steel belts placed underneath tread layers to enhance stability and grip.

With increasing demands for fuel efficiency and environmental sustainability, tire manufacturers began exploring alternatives to traditional materials like petroleum-based synthetic rubber. Today, cutting-edge tire technology incorporates innovative composite materials derived from natural sources like soybean oil or dandelion roots.

These sustainable materials not only reduce carbon emissions associated with tire production but also enhance grip on wet surfaces while maintaining durability. In addition to material advancements tire tread patterns have also undergone extensive development over time.

Early treads were simple ribbed designs that provided minimal traction on challenging terrains or adverse weather conditions. Modern tire treads are meticulously engineered using computer simulations and extensive testing to optimize performance in diverse situations like wet roads or snowy surfaces.

The evolution of tires has been characterized by continuous innovation driven by safety concerns, environmental considerations, and consumers’ demanding expectations for performance. From primitive solid bands to today’s advanced composite structures incorporating intelligent systems, tires have come a long way in meeting our ever-evolving transportation needs while striving towards sustainability and enhanced safety on the roads.

The Need for Innovation in Tire Technology

The need for innovation in tire technology arises from several key factors that have driven the tire industry to constantly push boundaries and seek new solutions. Firstly, the demand for improved safety standards has become paramount as accidents related to tire failures continue to occur.

Traditional tires, although reliable, are not immune to incidents such as blowouts or sudden loss of pressure. Therefore, innovation in tire technology must focus on enhancing traction, grip and stability to minimize the risks associated with these incidents.

Secondly, environmental concerns have become a significant driving force behind the need for innovative tire technology. The production and disposal of tires contribute to pollution and waste.

As society becomes more environmentally conscious, there is a growing demand for eco-friendly alternatives that reduce carbon emissions and minimize landfill waste. Innovations in materials and manufacturing processes can help create tires that are not only longer-lasting but also more sustainable throughout their lifecycle.

Additionally, advancements in automotive technology have led to faster and more powerful vehicles hitting the roads. These vehicles require tires that can handle higher speeds while maintaining optimal performance levels.

The need for innovation is evident as traditional tires struggle to keep up with the evolving demands imposed by modern vehicles. Moreover, changing weather patterns have highlighted the importance of adapting tire technology accordingly.

As extreme weather events become more frequent due to climate change tires must be designed to effectively cope with varying road conditions such as heavy rain, snowstorms, or heatwaves. This necessitates innovations in tread patterns and rubber compounds that provide superior traction on wet or icy surfaces while maintaining durability under high temperatures.

Consumer preferences also play a crucial role in driving innovation within the tire industry. With an increasing emphasis on comfort and noise reduction during driving experiences, there is a need for quieter and smoother-riding tires that enhance overall vehicle performance characteristics.

Additionally, consumers are becoming more cost-conscious and seek long-lasting tires with reduced rolling resistance for improved fuel efficiency. Various factors including safety concerns, environmental awareness, the evolution of vehicles, changing weather patterns, and consumer preferences underscore the need for innovation in tire technology.

The tire industry must continuously invest in research and development to meet these challenges and improve performance across all aspects of tire design. By embracing innovation tire manufacturers can pave the way for a safer, more sustainable, and technologically advanced future of tires.

The Future of Tire Materials

Sustainable Materials in Tire Production

The role of sustainable materials in tire production is crucial in addressing the environmental impact of tire manufacturing. Traditional tires are predominantly made from non-renewable resources such as petroleum-derived synthetic rubber and carbon black. However, the shift towards sustainability has led to significant advancements in exploring alternative materials.

One such material is natural rubber sourced from sustainable plantations which reduces the reliance on fossil fuels. Additionally, researchers are investigating the use of recycled materials like old tires and rubber waste to create new tire compounds, minimizing waste and promoting circular economy principles.

These sustainable materials not only reduce the carbon footprint associated with tire production but also offer improved performance characteristics such as enhanced grip, durability, and reduced rolling resistance. By incorporating these eco-friendly materials into tire manufacturing processes, we can move towards a more environmentally conscious future while maintaining high-quality performance standards.

The Impact of New Materials on Tire Performance

New materials are set to revolutionize the performance of tires and are pushing the boundaries of safety, durability, and efficiency. One such material is graphene, a single layer of carbon atoms arranged in a hexagonal lattice.

With its exceptional strength and flexibility, graphene has the potential to enhance tire performance in numerous ways. Its incorporation into tire compounds can significantly improve their grip on both wet and dry surfaces, reducing braking distances and enhancing overall handling capabilities.

Furthermore, the superior thermal conductivity of graphene allows for improved heat dissipation during high-speed driving, reducing the risk of blowouts and enhancing tire longevity. Another promising material is silica-reinforced rubber compounds.

Traditionally used as a filler material in tires to improve rolling resistance and wear characteristics, recent advancements have allowed for better dispersion of silica particles within rubber matrices. Silica reinforcement enables tires to maintain low rolling resistance without compromising grip or tread wear, leading to improved fuel efficiency.

Additionally, these enhanced compounds offer better traction on wet surfaces by effectively channeling water away from the contact patch. Moreover, nanomaterials such as carbon nanotubes (CNTs) have also shown great potential in improving tire performance.

CNTs possess remarkable mechanical properties which can strengthen tire structures while simultaneously reducing weight. By incorporating CNTs into tire sidewalls or tread reinforcement layers, manufacturers can design more lightweight yet robust tires that offer enhanced stability during cornering maneuvers and reduced rolling resistance.

The utilization of new materials like graphene, silica-reinforced rubber compounds, and carbon nanotubes in tire production holds immense promise for optimizing performance parameters such as grip and lower rolling resistance. These advancements in tire materials are poised to revolutionize both the driving experience and safety standards.

Intelligent Tires

The Concept of Smart Tires

In the ever-evolving landscape of tire technology, one concept that has gained significant attention is that of smart tires. Smart tires are a revolutionary advancement in the automotive industry, as they incorporate cutting-edge sensor and communication technologies to enhance performance, safety, and overall driving experience. These intelligent tires are equipped with built-in sensors that continuously monitor various parameters such as tire pressure, temperature, tread wear, and road conditions in real-time.

By collecting this crucial data smart tires provide valuable insights to both drivers and vehicle systems. For instance, utilizing pressure sensors embedded within the tire structure can alert drivers about any deviations from the optimal inflation levels. This information empowers drivers to take immediate action to address underinflated or overinflated tires before they compromise safety or fuel efficiency. Moreover, by monitoring the temperature in real-time, smart tires provide early warnings regarding potential overheating issues that can lead to blowouts or reduced tire lifespan.

Furthermore, the concept of smart tires extends beyond mere data collection and alerts. These advanced technological marvels can communicate with other vehicle systems using wireless technology like Bluetooth or Wi-Fi. By integrating with onboard computer systems or external devices such as smartphones or navigation units, smart tires enable seamless exchange of information for enhanced performance optimization. Imagine a scenario where your car’s control system receives data from your smart tires about poor road conditions ahead due to heavy rainfall or icy patches. Based on this input your vehicle’s traction control system could automatically adjust settings to ensure maximum grip and stability during these challenging circumstances. This integration not only improves safety but also enhances fuel efficiency by optimizing vehicle handling in real-time.

Smart tires have paved the way for a new era of connectivity between vehicles and their surroundings while revolutionizing how we perceive tire functionality. With their ability to collect critical data about tire health and road conditions in real-time while seamlessly communicating with other vehicle systems for enhanced performance, smart tires are poised to redefine the future of transportation.

The Role of Sensors in Future Tire Technology

Tire technology has undergone remarkable advancements in recent years, and one area that holds significant promise for the future is the integration of sensors.

These tiny high-tech devices have the potential to revolutionize how we understand and interact with tires. One key aspect of sensor integration in tire technology is real-time monitoring and reporting. Sensors embedded within the tire can provide crucial information about tire pressure, temperature, tread wear, and even road conditions. By continuously monitoring tire pressure, sensors can help prevent underinflation or overinflation situations that can compromise safety and fuel efficiency.

This information can be transmitted wirelessly to the vehicle’s dashboard or mobile applications, allowing drivers to promptly address any issues. Additionally, by monitoring temperature fluctuations within the tire, sensors provide early warnings about potential overheating problems that could lead to blowouts.

Another significant benefit of sensor integration is its ability to measure tread wear. Traditionally, drivers had to rely on visual inspection, periodic maintenance checks or rely on their mechanic to determine if their tires needed replacement. However, with sensors built into the tread pattern itself, they can provide precise data on tread depth and wear patterns in real-time. This not only helps optimize vehicle performance but also enhances safety by reducing the risk of hydroplaning on wet surfaces.

Moreover, with advancements in sensor technology paired with artificial intelligence (AI), these devices have the potential to go beyond basic monitoring functions. Sophisticated algorithms could analyze sensor data from multiple tires simultaneously and detect anomalies indicative of potential mechanical issues or irregular driving conditions. For instance, sudden drops in air pressure across multiple tires could signal a puncture caused by sharp debris on the road.

The integration of sensors not only enhances safety but also contributes to improved vehicle performance, fuel efficiency, and overall driving experience. As tire technology continues to evolve, the role of sensors will undoubtedly become even more integral, pushing the boundaries of what is possible in terms of tire innovation.

The Impact of Intelligent Tires on Safety and Efficiency

Intelligent Tires have the potential to revolutionize the automotive industry by significantly enhancing safety and efficiency on the roads. Through the integration of advanced sensors and smart technology, these tires are capable of collecting real-time data that can be utilized to improve overall vehicle performance.

One significant impact of intelligent tires on safety is their ability to monitor tire pressure and temperature continuously. By providing accurate information about these critical parameters, drivers can be quickly alerted to any abnormalities that may lead to tire failures or blowouts, thus preventing potentially dangerous situations on the road.

Additionally, intelligent tires can detect variations in road conditions such as wet or icy surfaces, and adjust traction control systems accordingly. This not only improves vehicle stability but also reduces the risk of accidents caused by loss of control due to unfavorable road conditions.

In terms of efficiency, intelligent tires contribute greatly by optimizing fuel consumption. By monitoring factors like rolling resistance and tread wear in real-time, these tires provide valuable feedback that allows drivers to adjust their driving behavior for better fuel economy.

For instance, when a tire’s pressure is appropriately maintained it decreases rolling resistance – resulting in reduced energy consumption and improved fuel efficiency. Moreover, intelligent tires can analyze data related to vehicle speed and acceleration patterns and suggest adjustments for more efficient driving techniques.

Furthermore, intelligent tires facilitate predictive maintenance practices by constantly monitoring various parameters related to tire health. They track tread wear patterns, detect irregularities in alignment or balance issues promptly, and provide early warnings when maintenance or replacements are required.

By proactively addressing potential problems before they escalate into emergencies or costly breakdowns on the road, intelligent tires help optimize maintenance schedules while minimizing downtime for vehicles. Given these significant impacts on safety and efficiency it’s clear that intelligent tires hold immense promise for shaping a safer and more sustainable future in transportation systems worldwide.

Airless Tires

The Concept and Benefits of Airless Tires

Airless tires, also known as non-pneumatic tires, are an innovative concept that is gaining momentum in tire technology. Unlike traditional pneumatic tires that rely on air-filled chambers for support and cushioning, airless tires are designed to be solid or filled with a resilient material. This revolutionary design offers several notable benefits.

One significant advantage of airless tires is their resistance to punctures. Traditional pneumatic tires are prone to flats caused by sharp objects on the road leading to inconvenience and potential safety hazards. Airless tires eliminate this concern entirely since they lack an internal chamber filled with pressurized air. This feature provides drivers with peace of mind, knowing that their tires can endure rough terrains without fear of sudden deflation or blowouts.

Furthermore, airless tires offer improved durability compared to their conventional counterparts. The absence of an inflated chamber minimizes the risk of damage from overinflation or underinflation.

Additionally, airless tire designs often employ resilient materials such as rubber composites or advanced polymers that enhance longevity and wear resistance even in challenging conditions.

Airless tires also contribute significantly to environmental sustainability by reducing waste generated from punctured or worn-out traditional pneumatic tires. As these non-pneumatic designs do not require regular replacements due to punctures or tread wear issues common in pneumatic versions, they effectively reduce tire waste and the associated environmental impact.

Airless tire technology has the potential to provide a smoother ride experience for drivers and passengers alike. By eliminating the impact caused by uneven inflation levels and enhancing stability through a solid construction or novel support structures within the tire design itself, these types of tires can absorb shocks more efficiently. This improvement translates into enhanced comfort for occupants while also reducing vibrations transmitted into the vehicle’s chassis.

Overall, the concept and benefits offered by airless tires demonstrate their promising potential in revolutionizing tire technology as we know it today. Their resistance to punctures, improved durability, eco-friendliness, and enhanced ride quality make them a compelling option for the future of mobility.

Current Developments in Airless Tire Technology

Airless tires, also known as non-pneumatic tires (NPT), have long been an area of interest for tire manufacturers and automotive enthusiasts alike.

One notable development in this field is the use of innovative materials that mimic the performance characteristics of air-filled tires while offering enhanced durability and resilience. One example of a material used in airless tire technology is a thermoplastic resin called polyurethane. This material is highly elastic and can withstand varying road conditions without compromising performance. Companies such as Michelin have made significant strides in developing airless tire prototypes utilizing this material, ensuring that these tires offer comparable comfort, handling, and grip to their traditional counterparts.

Advancements in manufacturing techniques have allowed for the production of intricate designs within the structure of airless tires. These designs facilitate efficient shock absorption and provide optimal traction on different surfaces.By incorporating distinctive tread patterns and innovative geometric designs on the outer surface, manufacturers aim to enhance grip while minimizing rolling resistance.

Additionally, another noteworthy development is the integration of customizable internal structures within airless tires to suit specific vehicle types or applications. By varying parameters such as stiffness or density within different sections of the tire’s structure, engineers can optimize performance attributes like cornering stability, noise reduction, or load-carrying capacity according to specific requirements.

Furthermore, ongoing research focuses on improving heat dissipation properties within airless tires to address one challenge associated with non-pneumatic designs – heat buildup during prolonged use. Innovations such as advanced cooling channels embedded within the tire structure help dissipate heat effectively while maintaining consistent performance levels. Overall, current developments in airless tire technology showcase promising advancements that aim to overcome limitations associated with traditional pneumatic tires.

Energy Generating Tires

Tires as a Source of Energy

The potential of tires as a source of energy is an intriguing concept that has gained considerable attention in recent years. As vehicles are constantly in motion, the idea of harnessing the rotational energy generated by tires and converting it into usable power holds great promise. This innovative approach presents several advantages, including the potential to enhance vehicle efficiency and reduce the environmental impact.

One avenue being explored is the utilization of piezoelectric materials embedded within tire structures. Piezoelectricity refers to the ability of certain materials to generate an electric charge when subjected to mechanical stress or deformation. By integrating these materials into tire designs, it becomes possible to harvest the vibrational energy produced during tire rotation and convert it into electrical energy.

Moreover, advancements in nanotechnology have opened up new avenues for enhancing tire capabilities as an energy source. The integration of nanogenerators within tires enables the conversion of various forms of mechanical energy, such as vibrations and deformations caused by road irregularities, into electricity. This method not only allows for energy generation but also presents opportunities for self-powering various automotive systems or even charging vehicle batteries. While still in its early stages of development, this technology shows tremendous potential for transforming tires into self-sufficient power generators. However, challenges persist in terms of optimizing efficiency and durability while maintaining safety standards.

Researchers are actively working on improving material properties and finding ways to integrate these technologies seamlessly into tire manufacturing processes. By tapping into the untapped potential within tires themselves, we can envision a future where vehicles can partly rely on their own wheels for sustainable power generation.

This would not only reduce dependence on traditional fuel sources but also contribute to a cleaner environment by lowering emissions associated with conventional power generation methods. Leveraging the inherent motion and deformation characteristics observed in tires enables us to explore exciting possibilities regarding their capacity as a source of renewable energy.

Research and Developments in Energy Generating Tires

With the increasing demand for sustainable and eco-friendly solutions, researchers and engineers have been working diligently to create tires that not only provide superior performance but also generate energy as a byproduct. Current research in this field primarily focuses on harnessing various forms of energy during tire rotation.

One approach involves integrating piezoelectric materials into the tire’s construction. These materials have the ability to convert mechanical stress into electrical energy. By strategically placing these materials within the tire’s structure, they can harvest energy generated as the tire flexes and deforms during normal driving conditions.

Another avenue of exploration in energy generating tires is through thermoelectric technology. This involves utilizing temperature differentials between the road surface and the tire itself to produce electricity. Specialized thermoelectric materials integrated into the tire absorb heat from friction with the road, which generates an electric current due to their unique properties.

Additionally, researchers are investigating how solar power can be harnessed by incorporating photovoltaic cells into the sidewalls or treads of tires. These cells would efficiently convert sunlight into electrical energy, providing a continuous source of power while driving under daylight conditions.

Developments in this field are still at an early stage but several prototypes have demonstrated promising results. For instance, recent tests conducted on vehicles equipped with energy generating tires have shown increased fuel efficiency due to reduced reliance on traditional charging systems for auxiliary components like lighting or sensor systems.

The potential applications for these advancements extend beyond conventional automobiles to other modes of transportation such as bicycles and electric scooters. Energy generating tires could significantly enhance their range and reduce dependency on external charging sources.

Despite these encouraging developments, there are challenges that need to be addressed before energy generating tires become commercially viable at scale. Issues such as durability, cost-effectiveness, and integration with existing vehicle systems all require further research and refinement.

Nevertheless, the progress made in this area fuels optimism about a future where our tires become active contributors to sustainable energy generation. By harnessing the power that is inherently dissipated during the process of driving, energy generating tires hold immense potential to redefine mobility and contribute to a greener world.

Eco-Friendly Tires

The Need for Eco-Friendly Tires

In our rapidly changing world, the need for eco-friendly solutions has become increasingly pressing and the tire industry is no exception. As concerns about climate change and environmental sustainability continue to grow, there is a crucial demand for tires that minimize their impact on the planet. The production and disposal of conventional tires contribute to significant environmental issues such as excessive rubber waste in landfills and the release of harmful chemicals during manufacturing processes.

To address these concerns, tire manufacturers are now actively exploring alternative materials and manufacturing techniques that can reduce their carbon footprint. One approach involves using sustainable materials like natural rubber from renewable sources rather than relying solely on synthetic rubbers derived from fossil fuels.

By sourcing rubber from eco-friendly plantations or using recycled rubber, tire manufacturers can significantly reduce their reliance on non-renewable resources while also supporting sustainable farming practices. Furthermore, eco-friendly tire technologies aim to enhance fuel efficiency by reducing rolling resistance.

Moreover, recycling initiatives have gained traction within the industry as a means of reducing waste and promoting sustainability. Tire manufacturers are investing in research and development efforts focused on developing effective methods for recycling used tires into new products such as asphalt additives or even incorporating them into new tire production processes. The need for eco-friendly tires arises from both environmental concerns and an understanding of the impact that traditional tire production has on our planet’s resources.

Innovations in Eco-Friendly Tire Technology

In recent years, there has been a growing emphasis on developing eco-friendly tire technology to address the environmental concerns associated with traditional tire manufacturing and disposal.

Tire manufacturers have been actively exploring various innovative approaches to reduce the carbon footprint and enhance sustainability throughout the entire lifecycle of a tire. One significant innovation in eco-friendly tire technology is the integration of sustainable materials into tire production.

Traditional tires are predominantly made from non-renewable resources such as petroleum-based synthetic rubber. However, manufacturers are now incorporating sustainable alternatives such as natural rubber derived from renewable sources like guayule or dandelion plants.

These alternative rubber sources not only reduce reliance on fossil fuels but also promote biodiversity by reducing deforestation linked to traditional rubber plantations. Moreover, advancements in recycling technologies have paved the way for innovative methods of reusing and repurposing old tires.

Tire recycling processes now go beyond simply shredding used tires into smaller pieces for civil engineering applications like road construction. Innovative techniques such as pyrolysis and devulcanization, allow for more advanced recycling methods that break down used tires into their constituent elements, enabling their reuse in new tire production or other industries.

Furthermore, eco-friendly tire technologies aim to minimize rolling resistance, which is responsible for a significant portion of energy consumption while driving and subsequently contributes to increased carbon emissions. By reducing rolling resistance through novel tread designs and optimized compound formulations, these eco-conscious tires not only improve fuel efficiency but also decrease greenhouse gas emissions.

Another noteworthy innovation focuses on improving the durability and longevity of tires to enhance their overall sustainability aspect. Long-lasting tires contribute significantly to reducing waste in terms of both manufacturing and disposal processes.

Manufacturers are investing in research and development efforts to formulate advanced compounds that provide superior tread wear resistance without compromising traction or safety performance. Some tire manufacturers are exploring innovative methods of producing self-healing or self-regenerating tires using environmentally friendly materials.

These tires contain special additives or compounds that can repair small punctures or cuts automatically, reducing the need for tire replacements and further extending their lifespan. Eco-friendly tire technology has witnessed remarkable advancements in recent years.

3D Printed Tires

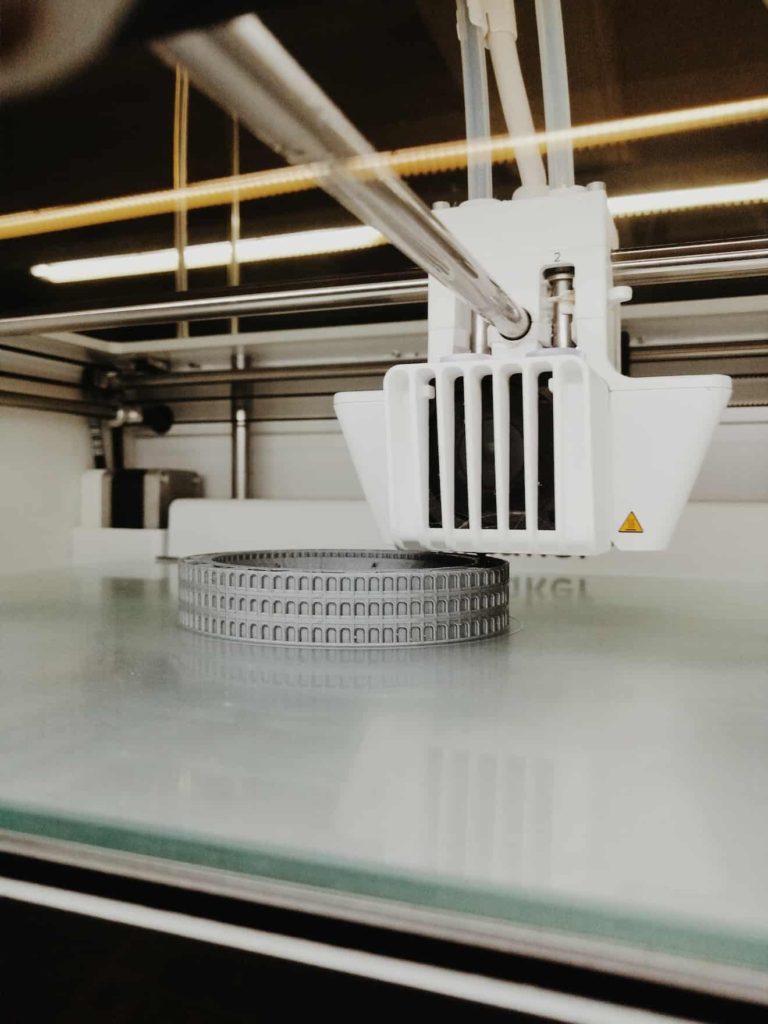

The Potential of 3D Printing in Tire Prodcution

The advent of 3D printing technology has opened up exciting possibilities for various industries, including the automotive sector. When it comes to tire production, 3D printing holds immense potential for revolutionizing the entire manufacturing process. One of the key advantages lies in its ability to create complex and customized designs that were previously unattainable using traditional manufacturing methods.

With 3D printing tire manufacturers can now create intricate tread patterns with enhanced precision, allowing them to optimize traction and grip based on specific road conditions or driving styles. This level of customization provides an opportunity to significantly improve both performance and safety aspects.

3D printing also enables the utilization of advanced materials that were not feasible with conventional tire production techniques. By utilizing specialized composite materials tailored for specific purposes, such as increased durability or fuel efficiency, manufacturers can enhance overall tire performance while reducing environmental impact.

This opens up avenues for creating tires that are not only safer and more efficient but also more sustainable. Another noteworthy advantage of 3D printing in tire production is its ability to minimize waste material compared to traditional manufacturing processes.

By using additive manufacturing techniques, excess material is significantly reduced as only the necessary amount is used in the fabrication process. This not only contributes to a more sustainable approach but also helps minimize costs associated with raw material consumption.

While there are still challenges to overcome before fully implementing 3D printed tires on a large scale – such as optimizing production speed and ensuring consistent quality control – ongoing research and development efforts show promising results. As technology continues to advance, we can expect further refinement and integration of 3D printing into the tire manufacturing process.

Current Advancements in 3D Printed Tires

In recent years, the field of 3D printing has witnessed remarkable advancements, and the tire industry is no exception. Researchers and engineers have been exploring the possibilities of using additive manufacturing techniques to revolutionize tire production and design.

One significant breakthrough has been achieved by Michelin, a leading tire manufacturer, with their development of the Vision concept tire. This concept introduces a completely airless structure that eliminates the need for traditional rubber compounds and replaces them with recyclable organic materials.

The Vision tire is created using 3D printing technology, allowing for customizability and adaptability to different driving conditions. Furthermore, another notable advancement in 3D printed tires lies in Bridgestone’s efforts to enhance sustainability through additive manufacturing techniques.

They have successfully developed a prototype called the “Air Free Concept,” which utilizes a unique structure comprising an intricate web of thermoplastic resin spokes instead of relying on air pressure for support. These airless tires offer benefits such as reduced waste during production and increased durability, as they are not susceptible to punctures or blowouts like traditional tires.

Moreover, companies like Continental have explored 3D printing technology to improve performance aspects such as grip and traction. By designing specialized tread patterns using precise layering techniques, they can optimize grip according to specific road conditions while maintaining overall durability.

Additionally, NASA has been conducting groundbreaking research on developing 3D-printed tires suitable for lunar rovers or future space exploration missions. Their approach involves utilizing innovative materials such as shape-memory alloys and regolith-based composites specifically engineered for extraterrestrial terrains.

Overall, these current advancements in 3D printed tire technology demonstrate how additive manufacturing techniques can significantly impact both sustainability and performance aspects within the industry. With further research and development we can anticipate even more groundbreaking innovations that will reshape not only how we manufacture tires but also how we experience driving on them in the future.

Big Data and AI in Tire Technology

How Big Data and AI Can Improve Tire Performance and Safety

Big data and artificial intelligence (AI) have emerged as powerful tools in various industries, and the field of tire technology is no exception. By harnessing the vast amounts of data collected from sensors embedded in modern vehicles, manufacturers can gain valuable insights into tire performance and safety. Firstly, big data analytics allows for comprehensive monitoring of tire health in real-time.

By continuously capturing data on variables such as tire pressure, temperature, tread wear, and road conditions, AI algorithms can analyze patterns and identify potential issues before they escalate into serious problems. This proactive approach to maintenance not only enhances safety but also extends the lifespan of tires by enabling timely interventions or replacements.

Moreover, big data and AI enable predictive modeling to optimize tire design and performance. By analyzing massive datasets related to driving behavior, environmental conditions, road types, vehicle weight distribution, and other factors influencing tire performance, manufacturers can develop more accurate models that simulate real-world scenarios.

These simulations help enhance grip levels on different surfaces while minimizing rolling resistance for improved fuel efficiency. Additionally, AI algorithms are capable of fine-tuning parameters like tread pattern design or rubber compound composition by learning from historical data gathered from a diverse range of driving conditions.

Furthermore, the combination of big data analytics with AI enables the creation of advanced driver assistance systems (ADAS) that actively enhance safety on the road. By integrating tire sensor information with other vehicle sensors such as ABS (Anti-Lock Braking System) or ESC (Electronic Stability Control), AI-powered systems can detect potentially dangerous situations like aquaplaning or loss of traction more accurately and respond instantaneously to prevent accidents.

Real-time monitoring of tire temperature variations also aids in early detection of abnormal heat buildup during long drives or high-speed maneuvers. Leveraging big data analytics and artificial intelligence has immense potential for improving both tire performance and safety aspects.

Current Applications of Big Data and AI in Tire Technology

Tire manufacturers along with automotive companies are using advanced sensors embedded within tires to gather real-time data on various parameters such as tire pressure, temperature, wear patterns, and road conditions. By harnessing this wealth of information through big data analytics and combining it with AI algorithms, manufacturers can gain valuable insights into tire behavior in different environments and usage scenarios.

This enables them to develop more accurate predictive models for detecting potential issues like tread wear or underinflation before they become critical safety concerns. Furthermore, by continuously monitoring these parameters through connected systems, drivers can receive automated alerts or notifications about tire maintenance requirements or potential risks.

Another exciting application of big data and AI in the context of tires is fuel efficiency optimization. Through the analysis of extensive datasets containing information on factors such as vehicle speed, weight distribution, road conditions, weather patterns, driver behavior, and tire performance metrics like rolling resistance coefficient or grip levels; researchers can develop intelligent algorithms that determine the optimal inflation pressure for maximum fuel efficiency.

This innovative approach allows vehicles to adapt their tire pressures dynamically based on real-time conditions to minimize energy losses resulting from inefficient rolling resistance while maintaining optimal grip levels for safety purposes. Such systems have shown promising results in reducing fuel consumption significantly without compromising vehicle performance.

Moreover, big data coupled with artificial intelligence is utilized in designing bespoke tires tailored to specific customer needs. By analyzing vast amounts of customer feedback along with demographic information such as geographic location preferences and driving habits; manufacturers can develop unique profiles that guide the production process.

This personalized approach ensures that customers receive tires optimized for their specific requirements regarding grip levels on different surfaces (e.g., wet roads versus dry roads), noise reduction capabilities, durability, and fuel efficiency.

The Impact of Future Tire Technology on the Automotive Industry

How Future Tire Technology Wil Influence Vehicle Design

In the ever-evolving landscape of automotive engineering, the future of tire technology holds tremendous potential to reshape vehicle design.

As advancements in tire technology continue to push boundaries, manufacturers and designers are presented with new opportunities to optimize both form and function. This section explores how future tire technologies will influence vehicle design, focusing on two key aspects: aerodynamics and space utilization.

Aerodynamics

One significant way in which future tire technology will impact vehicle design is through improved aerodynamics. Traditional tires often create drag and turbulence as they rotate, leading to increased fuel consumption and reduced overall efficiency.

However, emerging technologies such as airless tires or those with optimized tread patterns can significantly reduce drag by enhancing airflow around the wheels. By streamlining the interaction between tires and the surrounding air, vehicles can experience reduced wind resistance, resulting in improved fuel economy and enhanced performance.

Designers will have more freedom to explore sleeker profiles with lower ground clearance while ensuring optimal tire performance – a paradigm shift that could ultimately reshape the aesthetics of automobiles.

Space Utilization

Another aspect influenced by future tire technology is space utilization within vehicles. Currently spare tires take up valuable cargo or passenger space in many vehicles. However advancements like run-flat tires or puncture-resistant materials may eliminate the need for a spare tire altogether – enabling automakers to free up crucial space within their designs for increased storage capacity or interior comfort.

This development opens up possibilities for more versatile cabin layouts or even entirely new vehicle concepts that prioritize passenger comfort and convenience over traditional constraints associated with carrying a spare wheel. By reimagining traditional constraints imposed by conventional tire designs, future innovations will allow automotive designers to unleash their creativity while simultaneously improving performance metrics such as aerodynamics and space utilization.

The Impact on the Automotive Industry

The potential impact on the automotive industry: As tire technology continues to advance, its potential impact on the automotive industry cannot be overlooked.

One major area where this impact can be witnessed is in the design of vehicles themselves. With the development of airless tires, for example, automakers can rethink and redefine the design of vehicles.

Since airless tires do not require traditional rims and pneumatic systems, they offer greater flexibility in terms of vehicle architecture. This means that designers can explore new possibilities in terms of aesthetics, aerodynamics, and even interior space utilization. Imagine sleek futuristic vehicles with unconventional shapes made possible by the use of airless tires.

Furthermore, as intelligent tire technology becomes more prevalent, it will have a profound effect on vehicle safety and efficiency. Smart tires equipped with advanced sensors can provide real-time data about road conditions, tire pressure, temperature, and even tread wear. This information is invaluable to both drivers and automakers alike. It allows drivers to make informed decisions while on the road and helps manufacturers optimize their designs for better performance and durability. In addition to safety benefits, intelligent tire technology also has implications for vehicle efficiency.

By constantly monitoring tire conditions and providing data-driven insights regarding fuel consumption or optimal driving strategies based on road conditions or weather patterns, intelligent tires can contribute to significant fuel savings for vehicles.

As governments around the world continue to tighten regulations concerning carbon emissions and sustainability goals become more pressing than ever before – automakers are under increasing pressure to produce greener vehicles that align with these objectives. Manufacturers will need to adapt their production processes to incorporate eco-friendly materials into their tire manufacturing practices without compromising performance or safety standards.

The shift toward sustainable materials such as natural rubber alternatives derived from renewable sources or recycled materials will shape both tire design choices made by automakers as well as consumer purchasing decisions. The future of tire technology has far-reaching implications for the automotive industry.

Conclusion

The future of tires holds immense promise for a safer, more sustainable, and efficient automotive industry. Through advancements in materials science, intelligent technologies, airless designs, energy generation capabilities, eco-friendly solutions such as low rolling resistance compounds or 3D printed tires – coupled with the integration of big data analytics and AI – we are witnessing a transformative shift that will shape the way we drive for years to come.

As these innovations continue to evolve and gain mainstream adoption, consumers can look forward to an enhanced driving experience while minimizing their environmental impact. The future is indeed bright for tires – paving the way towards a safer and greener future on our roads.