Wheel Chocks

In the realm of vehicle safety and stability, there exists a humble yet indispensable tool known as the wheel chock. This unassuming device plays a crucial role in preventing unintended movement of vehicles or equipment, ensuring the well-being of both operators and bystanders.

By providing an effective means of immobilization, wheel chocks have found their place in various industries and applications where safety is paramount. In this article we will delve into the intricacies of wheel chocks, exploring their definition, functions, benefits, and different types.

What are Wheel chocks?

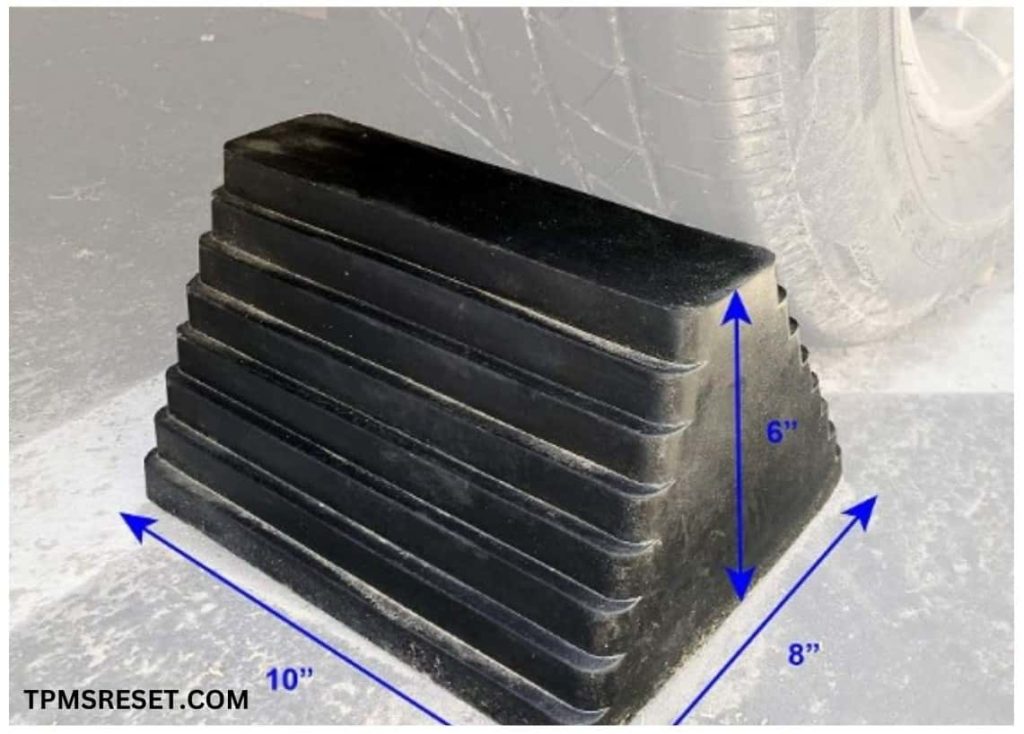

A wheel chock can be defined as a sturdy object designed to be placed against the wheels of a stationary vehicle or piece of equipment to prevent it from rolling or shifting unintentionally. It acts as a mechanical barrier between the tires and the ground or other surfaces, creating friction that resists movement. The shape and size of wheel chocks may vary depending on their intended use and the specific vehicles they are designed to immobilize.

Importance of Wheel chocks in Differnt Industries

The importance of wheel chocks cannot be overstated when it comes to safeguarding lives and property across multiple industries. These unassuming tools find utility in numerous applications where vehicles or heavy machinery are involved:

Automotive Industry

In automobile manufacturing plants, repair shops, or car parks, wheel chocks are used to secure vehicles during maintenance procedures such as tire changes or underbody inspections. They also serve as an extra precautionary measure when loading/unloading vehicles onto trucks or trailers.

Aviation Sector

While larger aircrafts use sophisticated landing gear mechanisms for stability on the ground, smaller planes require additional support during parking operations or maintenance work. Wheel chocks ensure that the aircraft remains stationary and prevents any unintended rolling or shifting.

Construction Sites

In the dynamic environment of construction sites wheel chocks play a vital role in ensuring stability during loading/unloading operations on inclined surfaces or uneven terrains. By preventing trucks, cranes, or heavy machinery from moving unintentionally they eliminate potential hazards and minimize accidents.

Marine Industry

Boatyards, marinas, and shipyards rely on wheel chocks to maintain the stability of vessels during maintenance tasks such as hull cleaning or engine repairs. These chocks secure boats in place and prevent them from slipping off trailers or rolling into hazardous areas.

Recreational Vehicles and Trailers

For enthusiasts who embark on adventures with their recreational vehicles, wheel chocks provide peace of mind by ensuring that trailers remain stationary at campsites or while hitched to a towing vehicle. This prevents accidents caused by unwanted movement.

The examples mentioned above merely scratch the surface of the myriad applications where wheel chocks are employed. Their importance cannot be overstated when it comes to ensuring safety, preventing accidents, and maintaining stability across various industries.

Overview of Wheel Chocks

Basic Design and Construction

When examining the basic design and construction of wheel chocks, it becomes evident that these simple yet effective safety devices are available in a variety of materials such as rubber, plastic, and metal. Each material offers distinct advantages based on its specific characteristics.

Rubber wheel chocks for instance are widely used due to their ability to provide a high friction coefficient that enhances grip on various surfaces. They are also known for their lightweight yet durable nature, making them easy to handle and transport.

On the other hand plastic wheel chocks boast excellent weather resistance and corrosion protection. This makes them suitable for outdoor use in harsh environments. Metal wheel chocks are highly robust and can withstand heavy loads with ease.

Purpose of Wheel Chocks

The primary purpose of a wheel chock is to prevent unintentional movement of vehicles or equipment. These tools play an invaluable role in maintaining safety during loading, unloading, or maintenance procedures across many industries. By strategically placing wheel chocks in front or behind the wheels of a stationary vehicle or machinery, they act as a powerful barrier against rolling or shifting.

This crucial function helps prevent accidents caused by unexpected motion that are minimized or completely avoided altogether. Wheel chocks provide an additional layer of security when used in conjunction with parking brakes since they offer extra stability for parked vehicles on inclines or uneven terrains. Even after pulling or pressing the hand brake you will notice that your vehicle will still roll a quarter wheel turn or so. Wheel chocks prevent this.

The importance of utilizing appropriate wheel chocks cannot be overstated as they not only safeguard lives but also protect valuable assets from damage caused by runaway vehicles or equipment. Their versatility allows them to be utilized across various industries including automotive repair shops, construction sites, warehouses, marine terminals, and aviation facilities where safety is paramount during numerous operational activities.

Understanding the fundamental design elements and purposeful nature of wheel chocks lays the foundation for comprehending their significance in maintaining safety and preventing accidents. These unassuming yet indispensable devices effectively immobilize vehicles or equipment while ensuring peace of mind for individuals working in potentially hazardous environments.

Functions and Benefits of Wheel chocks

Maintaining Stability on Flat Surfaces

When it comes to preventing rolling or shifting on flat or slightly hilly surfaces, wheel chocks emerge as a reliable tool. By strategically placing them under the tires the chocks create friction, thereby inhibiting any unintended movement. To maximize their effectiveness wheel chocks often adopt a practical wedge-shaped design.

This design ensures that the force applied to the chock is transferred to the ground through a perpendicular angle that results in optimal grip and resistance against vehicle motion. When used in conjunction with parking brakes, wheel chocks offer an additional layer of security by acting as a backup measure against any potential brake failure.

Protection Against Wheel Rolling or Movement

Wheel chocks play an instrumental role in preventing accidental vehicle movement during repair or maintenance work. Anytime I work on my vehicle in the driveway and am removing a wheel, I always use wheel chockes to make sure my car doesn’t roll.

They also provide vital support when securing heavy machinery during inspections or adjustments, ensuring the safety of both workers and the equipment itself. These dependable tools prove invaluable while loading or unloading cargo from trailers by supporting them and preventing potentially dangerous tipping accidents. This becomes particularly crucial in industries such as logistics and shipping where stability is paramount even on inclined surfaces or uneven terrains found on construction sites, shipyards, and off-road environments.

Types of Wheel chocks

Rubber Wheel Chocks

Rubber wheel chocks possess numerous advantages that make them highly popular among different users. Their high friction coefficient allows for increased grip between the tire and surface, providing excellent traction even in slippery conditions. Additionally, rubber wheel chocks are composed of lightweight yet durable materials that strike the perfect balance between portability and strength.

Common applications for rubber wheel chocks span across various vehicles including automobiles, trucks, motorcycles, as well as aircraft (particularly smaller planes), boats, and recreational vehicles. Their versatility and effectiveness make them a go-to choice in multiple industries where safety and stability are paramount concerns.

Metal Wheel Chocks

Metal wheel chocks offer distinct advantages that cater to heavy-duty applications. Built to withstand extreme conditions they exhibit exceptional durability and strength. These chocks are often made from robust metals like steel or aluminum to ensure they can endure significant weight loads and resist wear and tear caused by heavy machinery or rough terrains.

Ideal for industrial settings that involve large-scale equipment or oversized vehicles, metal wheel chocks provide reliable support when immobilizing massive loads. They offer peace of mind in critical situations where stability is crucial for safe operations.

Conclusion

In the realm of vehicle safety, wheel chocks take center stage as indispensable tools that serve a dual purpose—ensuring vehicle immobilization and enhancing overall safety. By effectively preventing rolling or shifting on flat surfaces through their wedge-shaped design and friction-creating properties, wheel chocks play a vital role in maintaining stability during various applications. Whether securing heavy machinery during inspections or supporting trailers while loading/unloading cargo to prevent tipping accidents, chocks prove themselves invaluable in safeguarding workers’ well-being and protecting valuable equipment.