Introduction

Imagine cruising down the open road, wind in your hair, and a sense of freedom enveloping you. As you enjoy this blissful moment it is crucial to remember that maintaining optimal vehicle performance and safety lies in the hands (or rather, the wheels) of one often overlooked component: tires. Among the essential aspects of tire maintenance is tire balancing—a fundamental process that ensures harmonious functioning between the wheels and their rubber companions.

What is Tire Balancing?

Tire balancing refers to the meticulous technique employed to rectify any imbalances present in a vehicle’s tires and wheels. These imbalances can arise due to various factors such as manufacturing defects, uneven tread wear over time, or simply old wheel weights falling off. When a tire is out of balance, it essentially means that its weight distribution is unevenly distributed around its circumference or on its wheel assembly.

The process primarily involves equalizing the weight distribution by attaching counterweights at designated spots on the wheel rim. These counterweights effectively offset any heavy points on the tire-wheel combination, ensuring smooth rotation at high speeds and minimizing vibrations that may compromise driving comfort.

Importance of Tire Balancing for Vehicle Performance

The significance of proper tire balancing cannot be overstated when it comes to enhancing both vehicle performance and safety. Firstly, balanced tires contribute significantly to improved handling characteristics. By eliminating excessive vibrations caused by imbalance, drivers can experience full control over their vehicles which lead to smoother steering responses and more precise cornering abilities.

Balanced tires promote even tread wear across all four tires of a vehicle—extending their lifespan significantly. Uneven tread wear can lead to premature degradation, compromising traction levels during acceleration or braking maneuvers.

By addressing imbalances promptly through regular tire balancing procedures, drivers can maximize both their safety on the road and the longevity of their tire investment. Furthermore, balanced tires reduce the stress exerted on other suspension components and minimize excessive wear on vital automotive systems.

Maintaining proper balance can also achieve fuel efficiency gains, as reduced rolling resistance translates into less strain on the engine and improved overall mileage.

Understanding Tire Imbalance

Causes of Tire Imbalance

Tire imbalance is a common issue faced by vehicle owners and can stem from various causes. One primary cause is manufacturing defects present in tires.

During the production process errors may occur in the distribution of rubber compounds or the positioning of internal components, leading to imbalances. These imperfections result in uneven weight distribution around the tire’s circumference, causing it to rotate irregularly.

Uneven wear is another prominent factor contributing to tire imbalance. As tires age and accumulate mileage they undergo natural wear and tear. However, often due to improper inflation or misalignment issues, this wear becomes uneven across the tread surface. Consequently, certain areas of the tire become lighter or heavier than others creating an imbalance that affects its rotational stability.

Tire imbalance is also commonly caused by older wheel weights falling off of wheels while driving the car. This usually happens when sticky wheel weights lose their stickiness and simply fall off the wheel.

Effects of Tire Imbalance on Vehicle Handling and Ride Quality

The consequences of tire imbalance extend beyond mere inconvenience; they directly impact both vehicle handling and ride quality. When a wheel/tire assembly experiences an imbalance, it induces vibrations that resonate through the entire vehicle structure. These vibrations can manifest as excessive steering wheel oscillation or shaking felt throughout the cabin during driving. (it will be felt fully at highway speeds)

Tire imbalance significantly compromises vehicle stability and maneuverability. As imbalanced tires rotate at high speeds they generate uneven forces acting upon suspension components and various mechanical systems within the vehicle.

This disturbance impairs precise control over steering inputs and undermines overall handling performance. Prolonged exposure to imbalanced tires can result in accelerated wear on suspension components such as shocks and struts since these parts need to compensate for the continuous disturbances caused by imbalanced rotations.

Ride comfort quality aspects such as noise levels are also affected by tire imbalance – a smooth ride is undoubtedly compromised when vibrations create excessive noise within a moving vehicle. Ultimately understanding both causes behind tire imbalance and its detrimental effects is crucial in recognizing the importance of tire balancing.

Tire Balancing Prcoess

Step 1: Mounting the Tires on the Balancing Machine

The first step in the tire balancing process involves mounting the tires onto a specialized machine designed for this purpose. This machine consists of several essential components, including the spindle and wheel flange. The spindle acts as the central axis or pivot point while the wheel flange securely holds the tire/wheel assembly in place during balancing.

Once mounted, the machine employs highly precise sensors and measuring systems to assess any imbalances present in the tire. These imbalances can occur due to various factors such as manufacturing defects or uneven wear over time.

The primary methods employed by these machines to measure imbalance are force variation and static imbalance. Force variation refers to fluctuations in forces acting on specific areas of a rotating assembly.

The balancing machine detects these variations by analyzing vibrations produced when spinning the tire at high speeds. By assessing these vibrations, technicians can identify areas with excess weight or mass that contribute to imbalance.

Static imbalance occurs when there is an uneven distribution of weight around the circumference of a tire/wheel assembly. To gauge static imbalance accurately, computerized systems within the balancing machine calculate weight discrepancies by comparing multiple points along its circumference.

Step 2: Identifying Heavy Spots on the Tire/Wheel Assembly

Once imbalances are detected using force variation and static imbalance measurements, technicians proceed to identify precise locations within the tire/wheel assembly that require corrective action. Various techniques are used for this purpose, with two common ones being wheel weights and chalk markings.

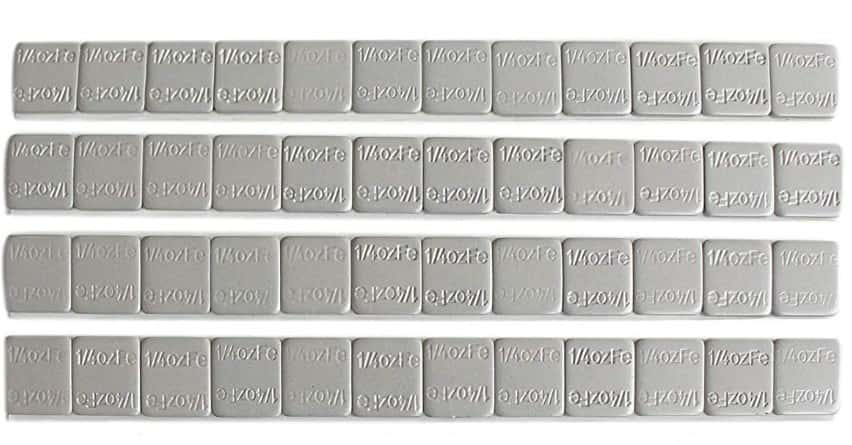

Wheel weights are often attached strategically at specific positions on a wheel rim’s inner or outer edge to counterbalance any excessive weight identified during measurement. These weights can be clip-on style or adhesive type depending on compatibility with different wheel designs.

Alternatively some technicians employ chalk markings instead of weights—a technique known as “match mounting.” The technician marks the lightest spot on the tire and the corresponding point on the wheel rim. This enables them to visually identify the heaviest area of the assembly allowing for precise placement of counterweights in step 3.

Accurate identification of heavy spots is crucial for effective balancing. Failing to pinpoint these locations precisely can result in an incomplete or ineffective balancing process leading to continued vibrations, uneven tire tread wear, and compromised vehicle handling.

Step 3: Applying Counterweights to Eliminate Imbalance

In this final step of the balancing process technicians apply counterweights to eliminate any identified imbalances. These counterweights can come in various forms depending on their compatibility with different wheel designs, including clip-on weights and adhesive weights. Clip-on weights are commonly used for steel wheels.

They are designed with a clamp-like mechanism that securely attaches them onto the wheel rim’s outer or inner edge. Their flexibility allows technicians to adjust their positioning accurately based on weight distribution requirements. To add a clip-on wheel weight a technician will line up where on the rim they want to add the weight and use a small hammer to bang it into place on the lip of the rim.

For alloy wheels or those without suitable surfaces for clip-on weights, adhesive weights offer a practical alternative. These specialized weights feature a sticky adhesive backing that allows them to be firmly attached directly onto specific locations along the inner or outer rim edge.

Placement techniques during this step vary depending on factors like weight distribution and wheel design. Technicians carefully consider these variables before applying counterweights—ensuring optimal balance is achieved by placing them at precise locations calculated from earlier measurements.

By meticulously following this three-step balancing process—mounting tires onto a balancing machine, identifying heavy spots accurately, and applying appropriate counterweights—technicians ensure that imbalances are effectively eliminated from tire/wheel assemblies. This meticulous attention to detail ultimately enhances vehicle performance, ride quality, and overall safety levels.

Dynamic Vs. Static Balancing

Striking a Balance

When it comes to achieving optimal tire performance, two methods reign supreme: dynamic balancing and static balancing. Though both techniques aim to rectify tire imbalance they approach the task from different angles. Understanding the distinction between these methods is crucial in comprehending the intricacies of tire balancing.

What is Dynamic Balancing?

Dynamic balancing is a technique that addresses both vertical and lateral imbalances in tires. Unlike static balancing, which only accounts for vertical imbalance when the wheel is stationary, dynamic balancing considers the continuous motion of the wheel as it rotates. This method identifies and rectifies imbalances caused by uneven weight distribution around the circumference of the tire.

To perform dynamic balancing specialized equipment such as a spin balancer is utilized. This sophisticated machinery spins the wheel at high speeds while sensors detect any imbalances present. By analyzing these readings technicians can pinpoint heavy spots on both the tire and rim assembly accurately. Once identified,corrective measures are taken by applying counterweights strategically.

These weights are chosen based on precise calculations accounting for weight distribution and wheel design. By precisely placing counterweights at specific locations on the rim assembly, technicians effectively neutralize vibrations caused by imbalances during rotation.

Conclusion

In the grand performance of the automotive symphony, tire balancing is the maestro conducting the harmonious interplay of weight distribution and motion, ensuring a smooth, controlled, and efficient ride. Its artistry lies not only in its scientific precision but also in the tangible impact it has on vehicle handling, fuel efficiency, tire longevity, and above all, safety. The roads we travel are an orchestra of movements and by understanding and implementing proper tire balancing—be it dynamic or static—we tune our vehicles to hit all the right notes, maximizing their performance and our enjoyment of every journey. As we peel away the rubber from the rim let’s appreciate the subtle yet significant role tire balancing plays, turning the wheels of motion into a masterpiece of mobility.