Introduction

Tightly securing the wheels of a vehicle is of paramount importance to ensure not only optimal performance but also the safety of passengers and other road users. Wheel lug nut torque plays a crucial role in this regard because it’s the primary mechanism for fastening the wheels onto the vehicle’s hub.

The proper application of torque to lug nuts is an essential aspect of automobile maintenance that should never be overlooked. In this comprehensive article we will delve into the intricacies of wheel lug nut torque, exploring what it is, understanding its significance, and emphasizing why it must be given utmost importance.

What is Wheel Lug Nut Torque?

Wheel lug nut torque refers to the amount of rotational force applied to secure the lug nuts on a vehicle’s wheels. It is typically expressed in terms of measurement units such as foot-pounds (ft-lbs) or Newton-meters (Nm).

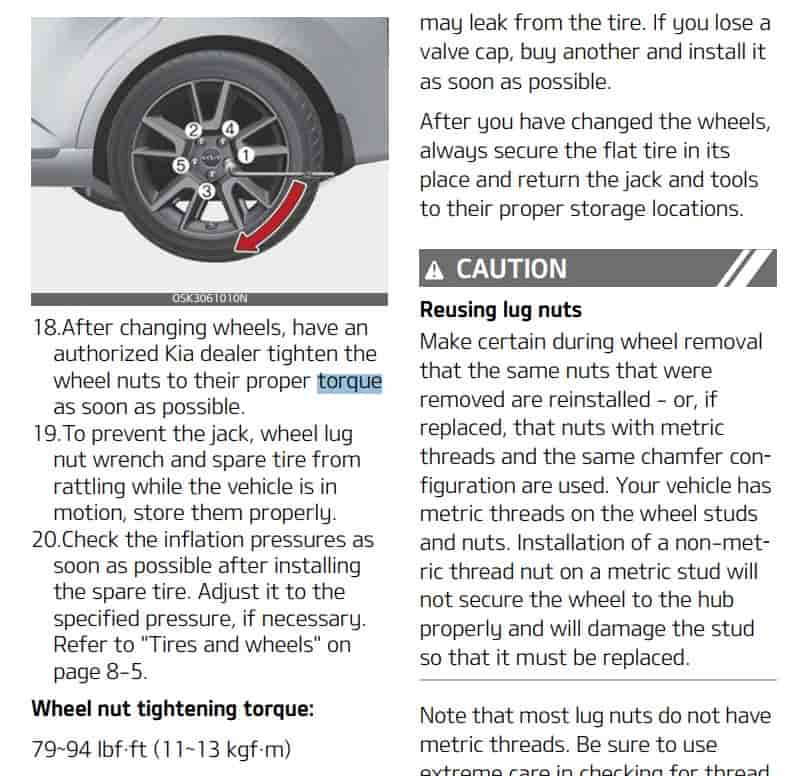

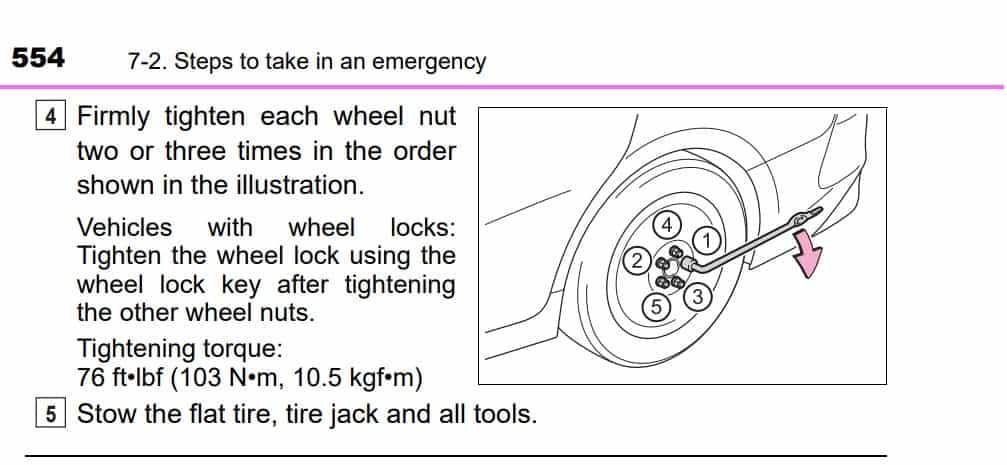

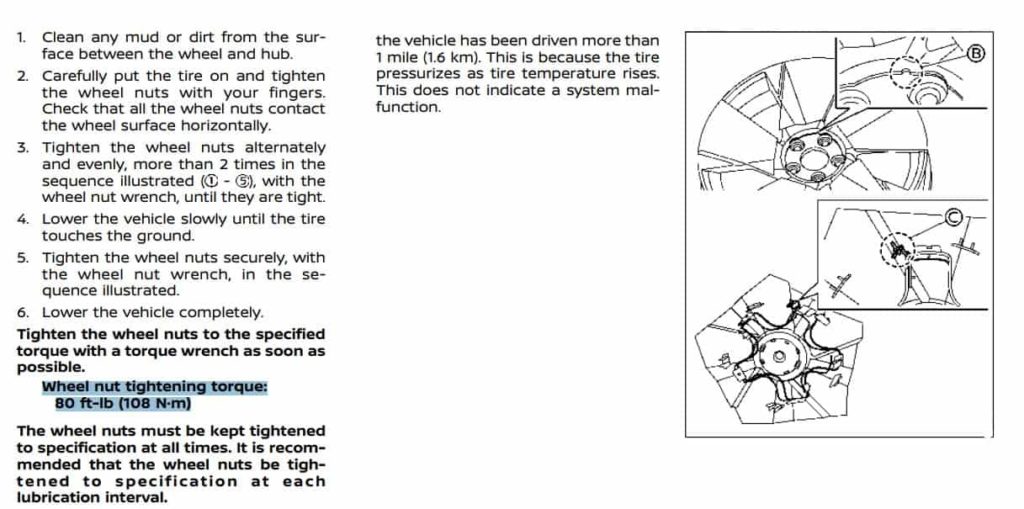

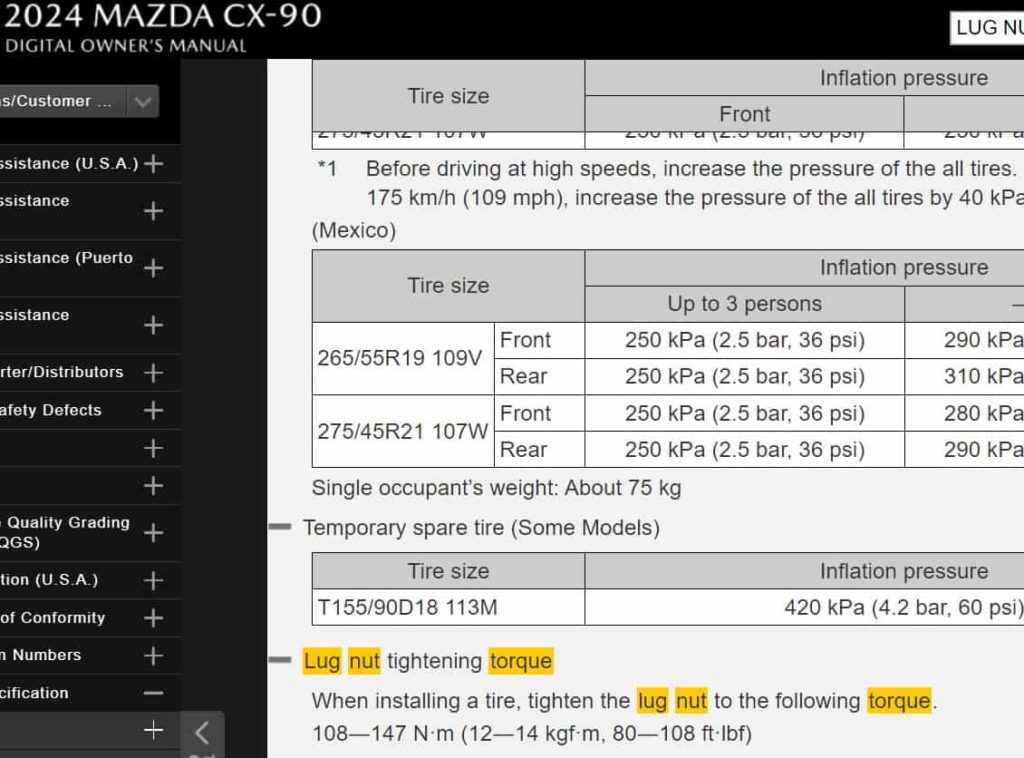

When tightening lug nuts a specific amount of torque needs to be applied to ensure proper fastening without damaging either the nuts or their corresponding threads. This torque value is determined by various factors such as vehicle make and model, wheel material, and manufacturer specifications.

While it may appear mundane at first glance understanding and implementing correct wheel lug nut torque is critical for several reasons. Not only does it provide structural integrity by preventing wheel detachment during operation but it also helps maintain optimal tire performance and extends the overall lifespan of both tires and wheels.

Adhering to recommended torque values helps mitigate potential risks associated with over-tightening or under-tightening lug nuts—both scenarios could lead to severe consequences such as premature tire wear, decreased fuel efficiency, increased vibration levels while driving, or even catastrophic accidents resulting from wheel separation on the road. In our next section we will dive deeper into comprehending wheel lug nut torque by familiarizing ourselves with different types of lug nuts and their components.

Understanding Wheel Lug Nut Torque

Definition and Components of Lug Nuts

Lug nuts are small but crucial components in the automotive world, serving as fasteners that secure wheels to a vehicle’s hub. These seemingly insignificant parts play a vital role in ensuring the safe and stable attachment of wheels, protecting both the vehicle and its occupants. Lug nuts come in various shapes and sizes designed to fit different wheel types and provide optimal performance.

Commonly used lug nuts include those with conical seat, ball seat, or flat seat designs. The conical seat lug nut features a tapered end that allows it to fit snugly into the corresponding conical-shaped hole on the wheel. This design ensures proper alignment between the lug nut and wheel, preventing any lateral movement that might compromise safety.

Ball seat lug nuts have a rounded end that fits into a spherical socket on the wheel. This design provides increased surface contact area between the lug nut and wheel, distributing forces more evenly during tightening or loosening processes. Flat seat lug nuts have a flat surface at their base and require washers for proper installation.

Torque and its Role in Lug Nut Tightening

To understand the significance of torque when it comes to tightening lug nuts, we must first grasp its definition within this context. Torque represents a rotational force applied to an object—specifically here—to tighten or loosen lug nuts securely onto or off of a vehicle’s wheels. In terms of tightening lug nuts, applying proper torque is crucial for maintaining safe and secure wheel attachment.

Adequate torque ensures that each individual lug nut is tightened with equal force across all fasteners securing a wheel to its hub. This uniform distribution helps prevent uneven stress on critical components such as brake rotors, studs, or hubs; thereby reducing the risk of damage or failure due to excessive strain.

Using the correct torque specification helps to achieve optimal clamping force between the wheel and hub assembly. This clamping force is essential for establishing a tight connection, preventing any movement or wobbling of the wheel during vehicle operation.

Insufficient torque may result in loose lug nuts leading to dangerous vibrations, potential loss of control, and ultimately compromising road safety. Conversely, over-torquing lug nuts can stretch or distort threads, weaken fasteners, or even cause damage to the wheel itself.

Factors Influencing Wheel Lug Nut Torque

Vehicle Manufacturer Specifications

The importance of adhering to the recommended torque values provided by the vehicle manufacturer cannot be overstated. These specifications are meticulously calculated and determined based on rigorous testing and engineering principles.

Straying from these guidelines can have serious consequences, compromising the safety and performance of your vehicle. Every vehicle make, model, and year has distinct characteristics that necessitate specific torque requirements.

This is due to variations in factors such as the weight distribution, suspension design, brake system configuration, and other mechanical aspects unique to each vehicle. As a result, manufacturers provide detailed torque specifications tailored for their vehicles to ensure optimal performance. You can find your vehicle’s specific torque in your user manual.

Wheel Material and Design Considerations

The choice of wheel material plays a significant role in determining the required torque for lug nuts. Steel wheels and aluminum alloy wheels have different mechanical properties that influence how they respond to torque. Steel wheels tend to be more rigid and less prone to deformation under stress compared to aluminum alloy wheels.

Aluminum alloy wheels possess a greater tendency for flexing under load due to their lighter weight and inherent flexibility. Consequently, they require specific torque values that compensate for this characteristic while ensuring proper clamping force on lug nuts.

Wheel design factors like thickness, number of lug holes or studs, cross-sectional shape, and even spoke patterns can impact lug nut torque requirements. These design considerations directly influence how evenly the clamping force is distributed across the wheel’s mounting surface when tightening the lug nuts.

Understanding the factors influencing wheel lug nut torque is crucial for maintaining safety while ensuring optimal performance of your vehicle’s wheels. By following the torque values recommended by the manufacturer and taking into account wheel material and design considerations, you can be confident that your wheels are securely attached and ready to withstand the challenges of the road.

Importance of Proper Wheel Lug Nut Torque

Safety Considerations

Ensuring the correct wheel lug nut torque is essential for maintaining safety on the road. When lug nuts are not tightened to the appropriate torque, it can lead to a range of dangerous situations.

Insufficient torque can result in loose wheels causing vibrations and potential wobbling while driving. This instability compromises vehicle handling and increases the risk of accidents.

Most importantly, improper lug nut torque can cause wheels to detach completely while in motion leading to catastrophic consequences. A loose or detached wheel poses a severe threat not only to the occupants of the vehicle but also to other drivers on the road.

The sudden loss of control due to a wheel detachment often results in devastating accidents with significant injuries or fatalities. Therefore, adhering to proper lug nut torque specifications is crucial for ensuring optimal safety on our roads.

How to Use a Torque Wrench

Begin by securing the lug nuts on your wheels by hand until they are finger-tight. Then, using a torque wrench apply the recommended level of torque. Your vehicle’s manual will specify the correct torque settings (usually measured in foot-pounds). To do this adjust the torque wrench to the required setting then tighten each lug nut in a star or crisscross pattern. This pattern is critical as it ensures an even distribution of pressure across the wheel. Be sure to apply slow and steady pressure on the wrench until you hear a click. This audible cue signals that the lug nut has reached the desired torque level. Always double-check each lug nut once you’ve gone through them all to ensure none have been missed or have loosened during the process.

Conclusion

Understanding and applying correct wheel lug nut torque is paramount when it comes to vehicle maintenance and safety. The proper tightening of lug nuts guarantees that wheels remain securely fastened, preventing potential accidents caused by instability or detachment.

Maintaining proper wheel lug nut torque not only protects lives but also preserves the integrity of your vehicle. It promotes a smoother ride by enhancing stability and reducing vibrational disturbances caused by loose wheels.

So let’s remember that paying attention to these seemingly small details plays a significant role in keeping ourselves and others safe on our journeys. Embrace this knowledge as you embark on your travels with confidence and peace of mind knowing that you have taken every precaution necessary for a secure ride.