If your TPMS light is on and your vehicles TPMS relearn procedure does not work, you need to learn about tire pressure system programming.

Tire Pressure Monitoring Systems (TPMS) are crucial for maintaining vehicle safety, offering real-time monitoring of the pressure inside each tire. These systems alert drivers to low tire pressure, which can lead to reduced fuel efficiency, increased tire wear, and, in worst-case scenarios, accidents. A low tire pressure light is also extremely annoying!

TPMS programming tools have revolutionized the way we maintain our vehicles TPMS sensors, ensuring tire pressures are always optimal and alerts are accurate.

Overview of Tire Pressure Monitoring System Technology

TPMS technology is designed to report real-time tire-pressure information to the driver of the vehicle either via the information display screen or a simple low-pressure warning light. There are two primary types of TPMS: direct and indirect.

Direct TPMS provides real-time tire pressure information from a TPMS sensor located in each of the four tires. Indirect TPMS works with the vehicle’s Antilock Braking System (ABS) wheel speed sensors to infer tire pressure from wheel speed. (Indirect TPMS system does not use programmable TPMS sensors)

Benefits of Using a TPMS Programming Tool

Programming tools for TPMS are not just for professional technicians. They offer several benefits for the everyday DIY’er that can save time and money. A TPMS scan tool allows for new sensor programming and diagnostic information to solve a flashing TPMS light.

Understanding Tire Pressure Monitoring Systems

Types of TPMS

Direct TPMS system uses tire pressure sensors mounted inside each wheel and directly measure the pressure in each tire, transmitting this data to the vehicle’s on board computer system.

Indirect TPMS does not use tire pressure sensors. Instead it uses the vehicle’s ABS system to monitor the speed of each wheel, indirectly measuring tire pressure based on rotational speed differences.

How Tire Sensors Work

Direct tire pressure monitoring systems consist of 4 tire pressure sensors, each with their own battery and transmitter. They measure the pressure and temperature inside each tire, sending this data via wireless radio frequency signals to the vehicle’s onboard computer. This system triggers a low tire pressure light to alert the driver in real-time if any tire falls below the recommended pressure level.

Choosing The Right TPMS Diagnostic/Programming Tool

When Do You Need a TPMS Programming Tool?

If your vehicle’s air pressure is correct yet the tire pressure light will not turn off with its standard TPMS reset procedure or the tire light is flashing, a TPMS programming tool is needed. It becomes necessary when installing new sensors, after a tire rotation, changing wheel or tire sizes, replacing sensors, and for seasonal tire changes. Additionally, it’s invaluable for system diagnostics, troubleshooting, and ensuring your TPMS is up-to-date with the latest technology.

Criteria for Selecting a TPMS Tool

Selecting the right TPMS programming tool involves considering the vehicle’s compatibility, the tool’s ease of use, and its range of features. It’s essential to choose a tool that supports a wide variety of vehicle models and makes, offers intuitive operation, and provides comprehensive diagnostic features.

Recommended TPMS Programming Tools

Several highly recommended tools on the market offer robust functionality and support for multiple vehicle models. These include the ATEQ VT56, the Bartec Tech400Pro, and the Autel MaxiTPMS TS508. Each has its strengths, such as extensive vehicle coverage, user-friendly interfaces, and advanced diagnostics capabilities.

How to Program Tire Sensors

Preparing for Sensor Programming

Before programming tire sensors, ensure you have all necessary equipment, including the TPMS programming tool, vehicle make and model information, and new sensors if replacements are needed. Preparation also involves making sure the vehicle is in a safe and stable condition for programming.

Programming Process Detailed

Initialization: Connect the TPMS tool to the vehicle via the OBD port and select the correct vehicle model and year.

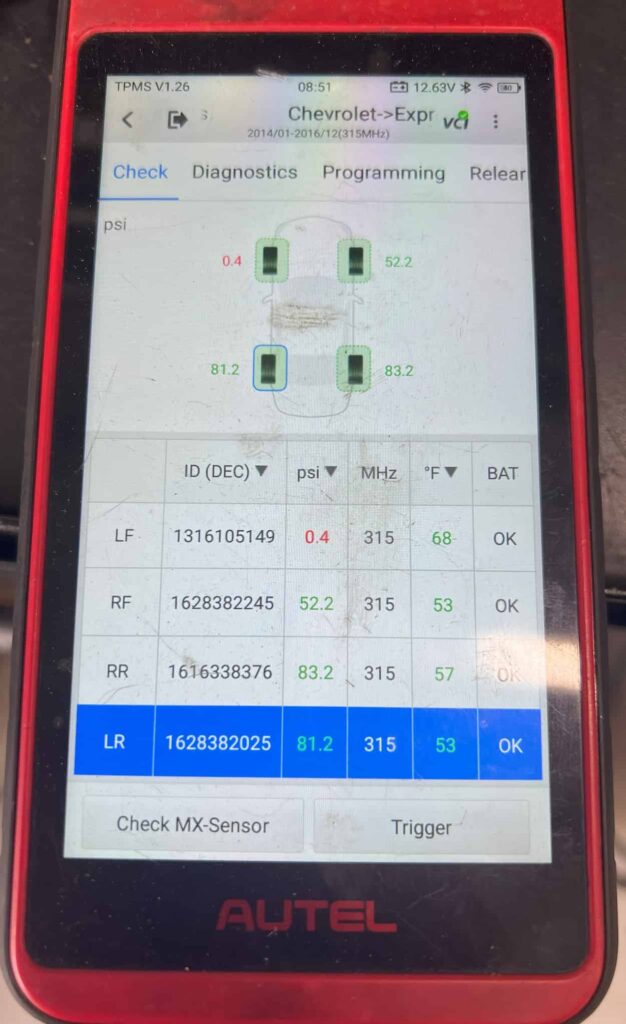

Sensor Detection: Place the tool next to the tire valve stem to detect and test the existing sensor. If replacing a sensor, ensure the new sensor is ready for programming.

Sensor Replacement: Remove the old sensor from the wheel and replace it with the new sensor. This usually involves removing the tire from the rim.

Programming: Follow the on-screen instructions on the TPMS tool to program each sensor to the vehicle’s TPMS system. This process may involve inputting new sensor IDs or copying the old sensor’s ID to the new sensor. Top of the line scan tools like Autel allow for “auto creation” where it takes care of all this automatically.

Verification: After programming, verify that each sensor is communicating correctly with the vehicle’s TPMS system. This may involve either re-initializing the sensors or driving the vehicle for a short distance to ensure all sensors are correctly reporting tire pressures.

Maintenance and Troubleshooting

Routine Maintenance of TPMS

Regular checks of the TPMS system and sensors can prevent failures. It’s advisable to check the TPMS system every time you service your vehicle or change tires. Sensor batteries typically last 5 to 10 years or up to 100,000 miles; however, they may need replacement sooner depending on usage and conditions. The Autel TPMS tools show the current battery status of each sensor during the sensor detection process to help determine how much time it has left.

Troubleshooting Common TPMS Issues

Common issues with TPMS include sensor failure, incorrect pressure readings, and communication errors between sensors and the TPMS tool. All of these instances will cause the tire pressure light on the dashboard to illuminate. In such cases, scanning each tire pressure sensor with a TPMS diagnostic tool will provide you with enough information to identify the exact issue and determine which sensor needs to be replaced to resolve it.

Frequently Asked Questions

Can I program tire sensors myself, or do I need a professional?

With the right TPMS programming tool, many drivers can program and diagnose their tire sensors. However, complex issues may require professional automotive technicians.

How often should I check my TPMS for accuracy?

It’s a good practice to check your TPMS system regularly, such as during routine maintenance or tire changes.

What do I do if a sensor is not communicating with the TPMS tool?

If a sensor does not communicate with the TPMS tool, that sensor battery is dead and the sensor needs to be replaced.

Are all TPMS tools compatible with any vehicle?

No, compatibility varies. Ensure the tool supports your vehicle’s make and model before purchasing.

Conclusion

Programming TPMS sensors with a TPMS tool is a straightforward process that can significantly enhance vehicle safety and get the low tire pressure light to turn off. By understanding the types of sensors, selecting the right programming tool, and following the step-by-step guide, drivers can ensure their vehicle’s TPMS system is accurate and reliable.

About the Author

STEFAN A.

Professional Automotive Technician – I am currently an automotive technician in New Jersey and have worked in private shops as well as dealerships. When I am not writing articles I am wrenching on race cars and driving radio controlled cars at the track!

Please note that this blog post contains Amazon affiliate links. This means that if you make a purchase through one of these links, we at TPMSRESET.COM may earn a small commission at no extra cost to you. We only recommend products that we personally use and believe in. Thank you for supporting us.