Vehicle safety and performance are paramount for every driver. Among the myriad of technologies that enhance these aspects, Tire Pressure Monitoring Systems (TPMS) stand out for their critical role in maintaining optimal tire pressure, thus ensuring safety, fuel efficiency, and prolonging tire life.

This article delves into the scientific principles and technical details behind tire pressure sensors, shedding light on how these small yet powerful devices communicate with vehicles to provide real-time tire pressure data.

What Are Tire Pressure Monitoring Systems?

Tire Pressure Monitoring Systems (TPMS) are advanced safety features that alert drivers to tire pressure issues, potentially preventing accidents caused by under-inflated tires. Initially developed as a luxury feature in high-end vehicles, TPMS has become a mandatory safety component in many countries, reflecting its importance in automotive safety. The evolution of TPMS technology from simple manual checks to sophisticated electronic systems marks a significant advancement in vehicle safety measures.

Are all TPMS the Same?

TPMS can be classified into two main types: Direct and Indirect.

Direct TPMS measures tire pressure directly from within the tire via sensors, providing accurate and real-time data.

Indirect TPMS, on the other hand, infers tire pressure indirectly by analyzing variations in wheel speed data. Both systems play a crucial role in enhancing vehicle safety, but they operate on entirely different principles and technologies.

The Science Behind Tire Pressure Sensors

Understanding how tire pressure sensors operate requires a deep dive into the types of sensors employed in TPMS and the scientific principles that govern their functionality. Tire pressure sensors are sophisticated devices designed to accurately measure the air pressure inside a tire and transmit this data to the vehicle’s onboard computer system.

There are several types of sensors used in TPMS, each utilizing different methodologies to achieve this goal: Piezoresistive, capacitive, and resonant frequency sensors are among the most common.

Types of Tire Pressure Sensors

Piezoresistive Sensors

Piezoresistive sensors are the most widely used type of sensor in direct TPMS setups. They operate on the principle that the resistance of a material changes under mechanical stress. In the context of tire pressure sensors, a piezoresistive material is incorporated into a pressure-sensitive element; as the tire pressure changes, it exerts more or less force on this element. This force induces a change in electrical resistance, which can be measured and converted into a pressure reading by the sensor’s microcontroller.

Capacitive Sensors

Capacitive sensors measure tire pressure by detecting changes in electrical capacitance caused by the deformation of a membrane when pressure is applied. These sensors comprise two conductive plates separated by a dielectric material. When the tire pressure changes, it causes one of the plates (the membrane) to deform, altering the distance between the plates and thus changing the capacitance. This change in capacitance is proportional to the air pressure inside the tire and is converted into an electrical signal for measurement.

Resonant Frequency Sensors

Resonant frequency sensors determine tire pressure by measuring changes in the resonant frequency of a membrane or cavity within the sensor. As tire pressure varies, it alters the tension on the membrane or changes the volume of the cavity, both of which affect the resonant frequency. This type of sensor is highly accurate and can measure both pressure and temperature, which are critical for precise tire pressure monitoring.

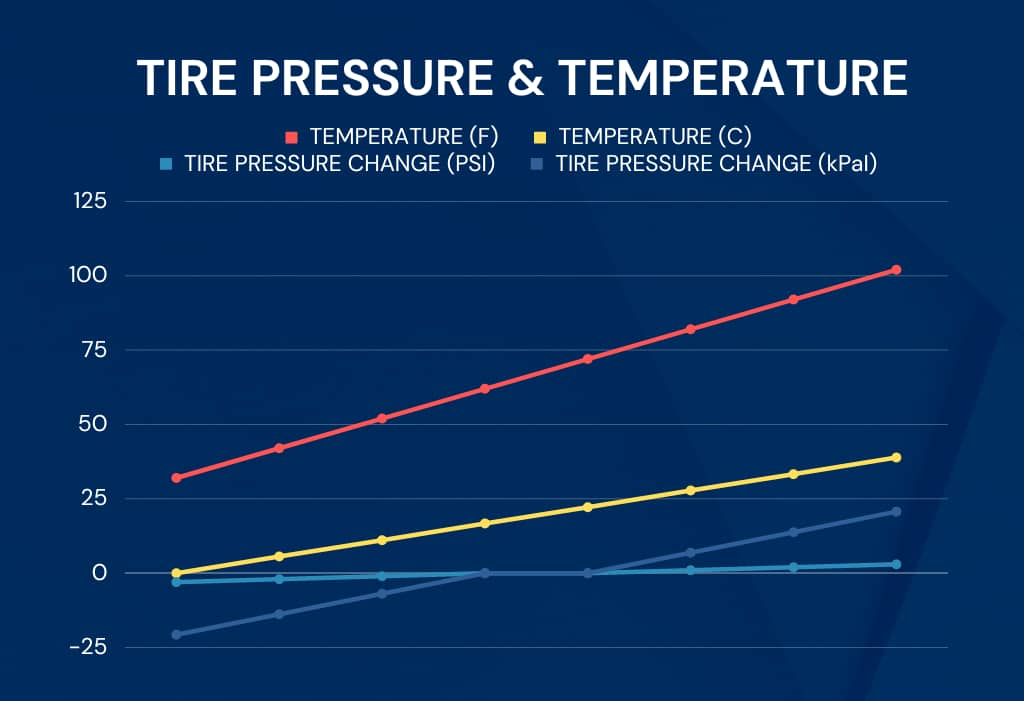

Temperature Compensation

An important aspect of tire pressure measurement is temperature compensation. Tire pressure can vary significantly with temperature changes, a phenomenon governed by the ideal gas law. To ensure accurate pressure readings, tire pressure sensors must account for temperature variations. This is achieved through integrated temperature sensors and sophisticated algorithms that adjust the pressure readings based on the measured temperature.

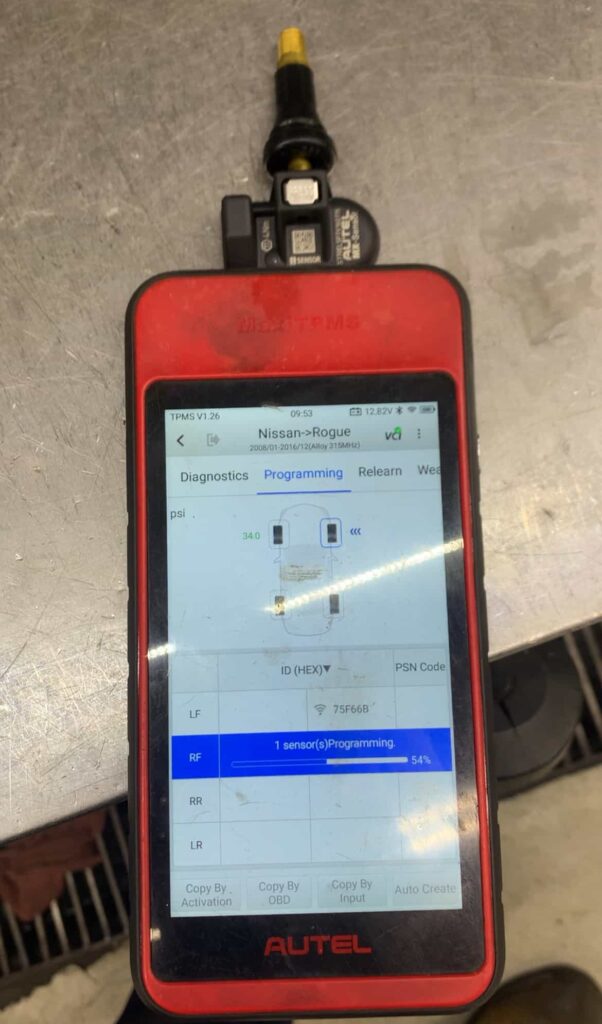

How Tire Pressure Sensors Communicate With the Vehicle

Once the tire pressure sensor has measured the air pressure and compensated for temperature, it needs to communicate this information to the vehicle’s onboard computer. This is typically done using radio frequency (RF) transmissions on a 315 mHz or 433 mHz frequency. Each sensor has a unique identifier that allows the vehicle’s TPMS receiver to distinguish between the signals from different tires.

The sensor transmits data packets that include the pressure reading, temperature (if available), sensor battery status, and its unique identifier. This data enables the vehicle’s computer to alert the driver if any tire is significantly under-inflated, enhancing safety and performance.

TPMS Components and Communication

Direct Tire Pressure Monitoring Systems represent a significant advancement in automotive safety technology. By providing real-time tire pressure information, they allow drivers to address potential safety issues before they become hazardous. A direct TPMS consists of several key components, each playing a vital role in its operation.

Anatomy of a Tire Pressure Sensors

A tire pressure monitoring system sensor is a compact, yet sophisticated device embedded inside the tire, typically mounted on the valve stem or wheel rim. Its primary components include:

Pressure Sensor: The heart of the TPMS sensor, utilizing either piezoresistive, capacitive, or resonant frequency technologies to measure the tire’s air pressure.

Temperature Sensor: Integrated within the TPMS sensor to provide temperature data, ensuring accurate pressure readings through temperature compensation.

Battery: Powers the sensor’s circuitry. These batteries are designed to last several years and miles but eventually require replacement.

Transmitter and Antenna: Enables the sensor to communicate wirelessly with the vehicle’s onboard computer system.

Microcontroller: Processes the pressure and temperature data, controlling the sensor’s functions and managing the data transmission.

Measuring Pressure and Transmitting Data

TPMS sensors operate autonomously, continuously monitoring the pressure and temperature inside the tire. When a significant change in pressure is detected, or at regular intervals, the sensor wakes from a low-power mode and measures the tire’s pressure. The microcontroller processes the data along with the temperature reading to calculate the tire’s actual air pressure, compensating for any temperature effects.

The processed data is then packaged with the sensor’s unique identifier and transmitted to the vehicle’s onboard computer via an RF signal. This signal is received by a dedicated TPMS receiver module within the vehicle, which decodes the data and checks it against the manufacturer’s recommended pressure levels.

Tire Pressure Light on the Dashboard

If the received data indicates that a tire’s pressure is outside the recommended range, the vehicle’s onboard computer triggers an alert for the driver. This alert typically appears on the dashboard as a low tire pressure warning light or a message on the dashboard display, indicating which tire is affected and whether the pressure is too high or too low. In newer vehicles the dash display may show the air pressure for each tire, allowing the driver to see the exact pressure levels in real time at a glance.

Communication Protocols and Vehicle Integration

The communication between TPMS sensors and the vehicle’s onboard computer relies on standardized RF communication protocols. These protocols ensure that the data transmission is secure, reliable, and interference-free, even in environments with multiple wireless signals. Additionally, modern vehicles integrate TPMS data with other safety and performance systems, such as electronic stability control and brake assist (ABS) which helps to enhance the vehicle’s overall safety and operational efficiency.

Tire Pressure Sensor Battery Life

Tire Pressure Sensor Maintenance: The sensors in a Direct TPMS are battery-powered, typically with a non-replaceable battery designed to last the sensor’s lifespan, usually 5 to 10 years. When the battery dies, the entire sensor must be replaced. Recognizing the signs of a failing sensor—such as inconsistent pressure readings, a flashing tire pressure light on the dash, or no readings at all—is crucial for timely maintenance.

TPMS Battery Replacement: Replacing a TPMS sensor involves removing the tire from the wheel to access the sensor mounted on the base of the valve stem. It’s often recommended to replace all sensors simultaneously due to similar battery lifespans, ensuring consistent system performance.

Common Tire Pressure Sensor Problems

False Alerts: Tire pressure monitoring systems can trigger false alerts due to sensor malfunctions, incorrect calibration, or environmental factors affecting sensor readings. Diagnosing these issues often requires specialized TPMS tools and knowledge of the vehicle’s specific TPMS configuration.

Sensor Damage: Physical damage to TPMS sensors can occur during tire changes or from impact with road debris. Regular inspections can help identify and prevent such issues.

FAQ

How are tire pressure sensors integrated with other vehicle systems such as electronic stability control and ABS?

Tire pressure sensors are integrated with vehicle safety systems such as electronic stability control (ESC) and brake assist through the vehicle’s onboard computer systems. The TPMS sensors provide real-time data on tire pressure, which is crucial for ESC and brake assist to function optimally. The integration involves standardized RF communication protocols that ensure the data transmission is secure and reliable, preventing interference from other devices.

What are the most common issues tire pressure sensors have as they age?

As TPMS sensors age, they may experience issues like battery depletion, air pressure inaccuracies, or physical damage (from road debris). To maintain their functionality, vehicle owners should regularly compare the dashboard tire pressure readings to a manual air pressure check using a tire pressure gauge. Drivers can also use a TPMS diagnostic tool to test and check each tire sensor’s health. If a sensor’s battery dies or it shows signs of malfunction (like inconsistent pressure readings or a flashing tire pressure light), it will need to be replaced.

What is the difference between factory-installed and aftermarket TPMS?

Factory-installed TPMS are integrated into the vehicle’s design and often communicate more seamlessly with the vehicle’s onboard diagnostic systems and dashboard display. Aftermarket TPMS might be used when upgrading a vehicle that didn’t originally include TPMS. These systems can vary in integration depth, sensor type, and overall functionality compared to OEM (original equipment manufacturer) systems.

About the Author

STEFAN A.

Professional Automotive Technician – I am currently an automotive technician in New Jersey and have worked in private shops as well as dealerships. When I am not writing articles I am wrenching on race cars and driving radio controlled cars at the track!

Please note that this blog post contains Amazon affiliate links. This means that if you make a purchase through one of these links, we at TPMSRESET.COM may earn a small commission at no extra cost to you. We only recommend products that we personally use and believe in. Thank you for supporting us.